We have outlined the main features of the Sine test in our previous article, and also mentioned some of its key limitations – Sine can only cover one wave frequency at a time. This makes it different to imitate real vibration conditions. In comparison, Random is a mathematical model, which successfully compensates for this drawback.

Random vibration testing involves subjecting a product or system to a broad spectrum of vibration frequencies simultaneously, mimicking real-world conditions. It allows engineers to evaluate the response and durability of the device under unpredictable vibrations encountered during transportation, or general use. As the amplitude and phase of such a signal are, by definition, random, just as the vibrations surrounding us, this test type does a much better job of simulating real-life noise impacts.

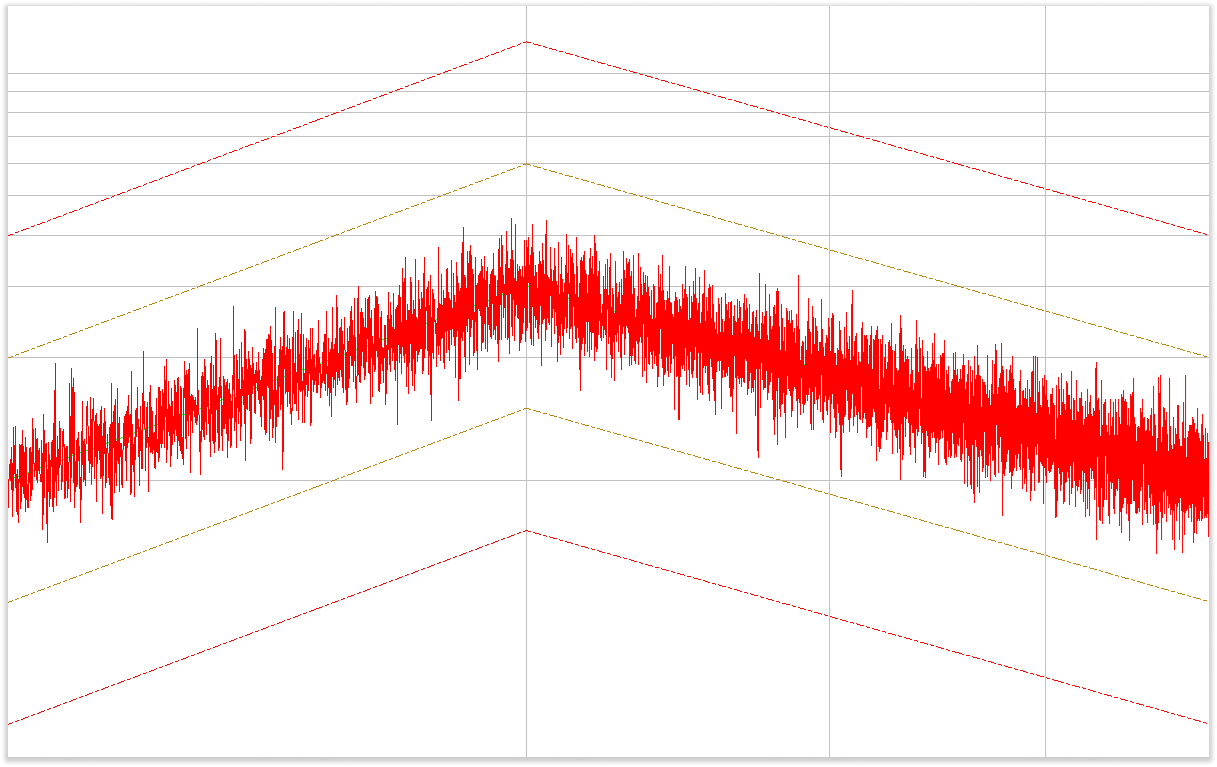

Figure 1 - Example of Random Signal

As opposed to the Sine test, with the Random test, we get a representation of all frequencies of the object in the specified range. This representation is often given in the form of a PSD (power spectral density) vs. frequency plot.

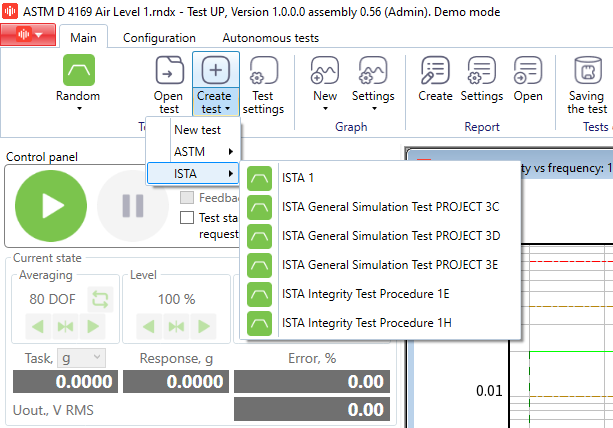

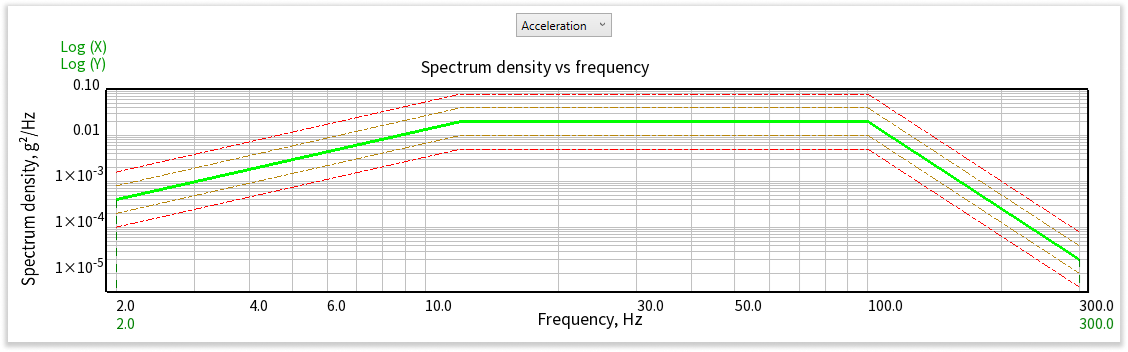

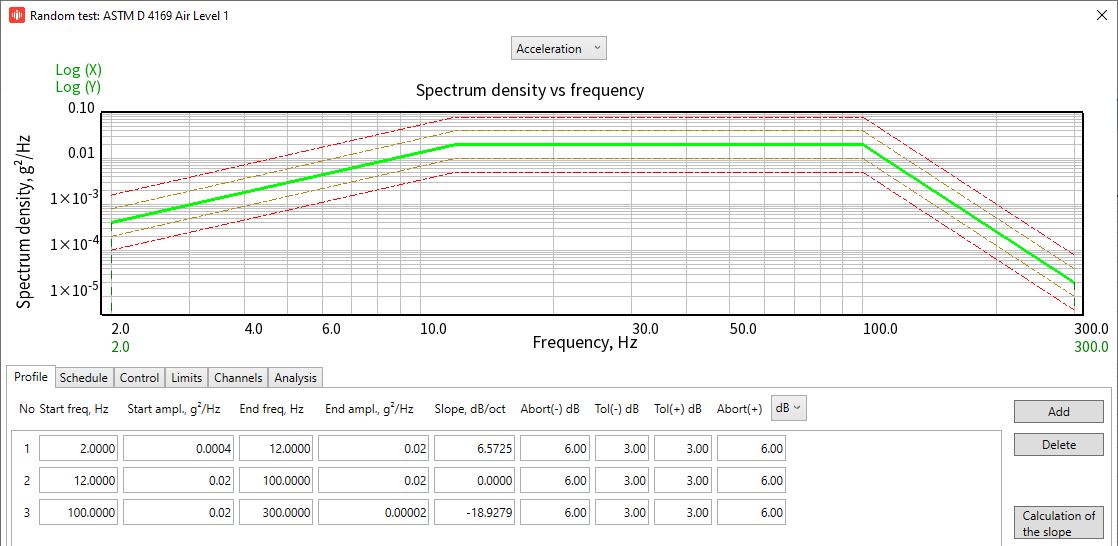

Figure 2 - Spectrum density vs. Frequency graph in TestUp software for vibration testing

PSD is a key characteristic of Random tests. It represents the distribution of the signal in the given frequencies. The units of PSD can be, for instance, G squared per Hertz (if acceleration is measured in G). To obtain the necessary PSD parameter, the algorithms of vibration control use Fast Fourier Transformation (or FFT), transforming the received time domain data in Gaussian distribution into frequency domain data.

In Figure 2, the area under the green task line is the signal mean square. If we calculate this area, we will receive the value of the signal acceleration RMS. The method of calculation is described in detail in our article “Common Formulas of Sine and Random”.

Typical Setup for Random Vibration Testing

A typical setup for Random vibration testing is no different than the standard vibration testing set, which involves a controller, a shaker table or electrodynamic shaker, a power amplifier, and the device under test (DUT) mounted on it. The shaker generates random vibrations with controllable intensity and frequency spectrum. The DUT's response is measured using accelerometers or other sensing devices strategically placed to capture critical points of interest.

A test engineer controlling the Random test should follow the common sense guidelines, applicable for every vibration test, as in:

- Thoroughly understand the product: gain a comprehensive understanding of the device being tested, including its intended application, materials, and potential weak points, to design effective test plans.

- Consider the product's operating environment: replicate the anticipated environmental conditions accurately, including temperature, humidity, and vibration patterns, for reliable and realistic results.

- Assemble and adequate object fixture: ensure secure mounting and appropriate fixture design to avoid unintended resonance or damping effects that may affect test outcomes.

Random Test Profile

To enter a Random test profile, you need to have the appropriate test specification, according to a relevant standard or DUT technical requirements. Here are the key parameters of a Random test:

- frequency

- amplitude

- the slope of each profile line.

Figure 3 - Random Test Profile window in TestUp vibration testing software

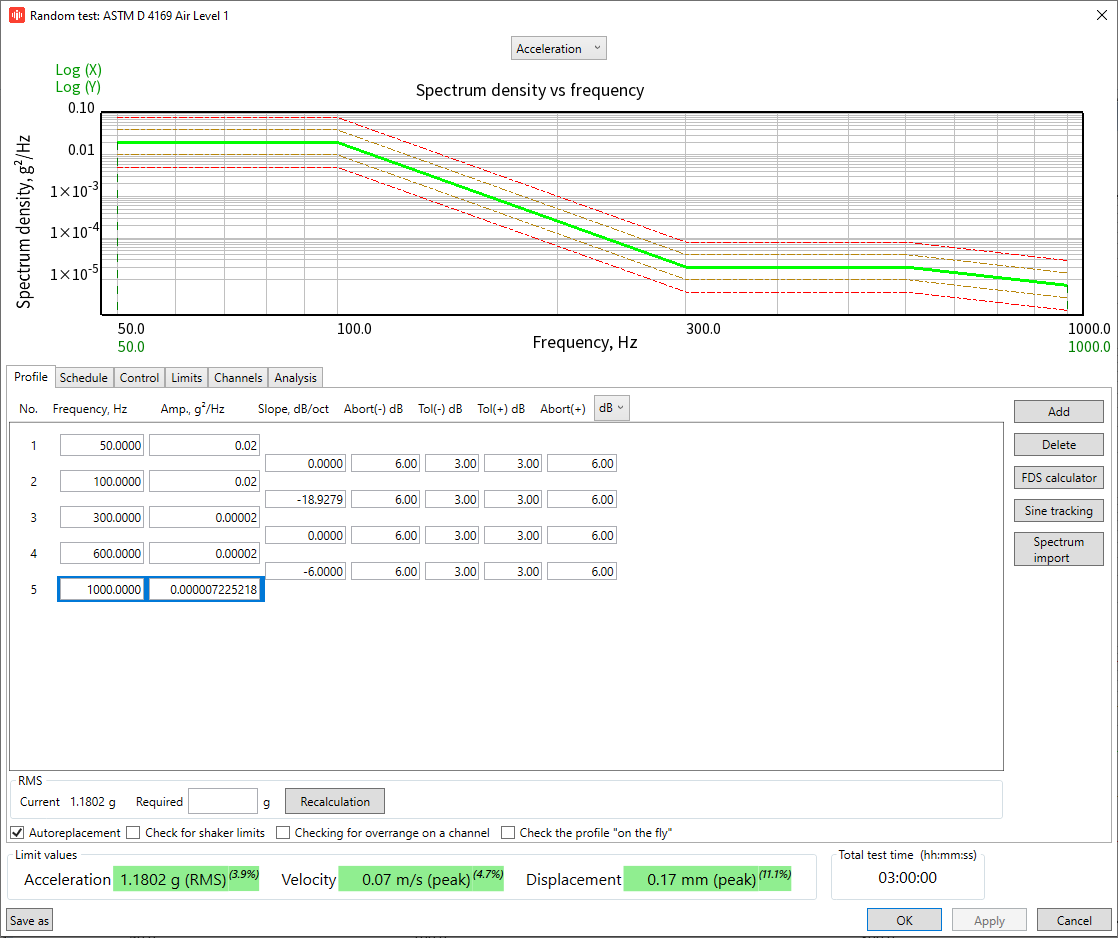

In our software package TestUp you can either enter the Random profile in lines of frequency, similar to the Sine test, or change the approach and enter the profile point by point. You can freely switch between two modes by changing the default settings. Each point will be characterized by a value of frequency and amplitude; each of them will be part of the resulting spectrum.

Figure 4 - Creating Random test profile by points in TestUp

Regardless of which method the engineer chooses (profile by points or profile in lines), having entered the Random test profile, the user can save it, and then run the same Random test with one button click.

Random Vibration Testing Standards

It becomes even easier if you apply a dedicated test standard for your random testing application. There are a number of international standards providing guidelines and specifications for conducting such tests in different industries. Here are some for them:

- MIL-STD-810G Method 514.6: commonly used in the defense industry to assess the ability of equipment to withstand random vibrations encountered during transportation, operation, or other environmental conditions.

- IEC 60068-2-64: focuses on testing electronic components and products against random vibrations. It provides guidance on test methods, test conditions, and measurement techniques. It includes specific profiles based on PSD.

- ASTM D3580: particularly relevant for transportation and packaging applications. It outlines test procedures and profiles for evaluating the ability of products and packages to withstand random vibrations experienced during transportation ranging from a few minutes to several hours.

- ISO 16750: This standard is specifically designed for the automotive industry and focuses on environmental conditions, including vibration.

- RTCA DO-160: Widely adopted in the aerospace industry, this standard covers environmental test procedures for airborne equipment in harsh operational environments.

- IEC 60068-2-6: This standard addresses the testing of equipment subjected to vibration in laboratory conditions. It includes a section on random vibration testing.

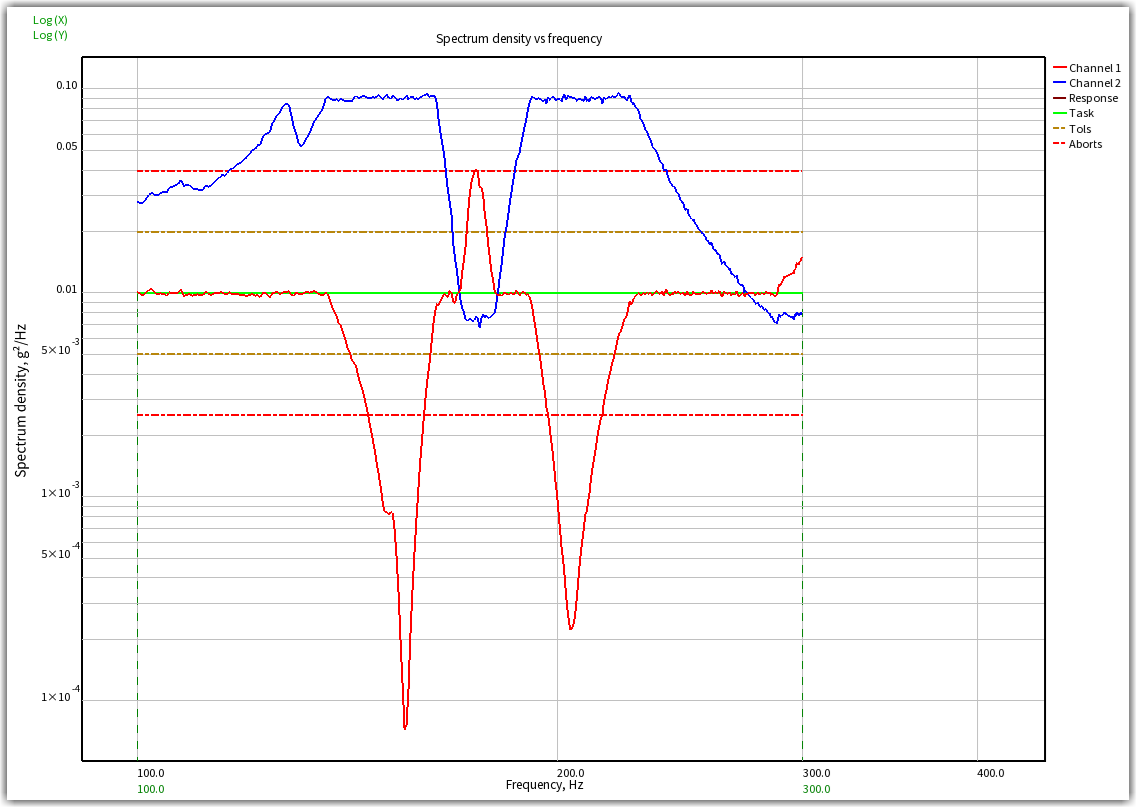

RULA keeps integrating various test templates with the most common testing standards, including those for Random tests. It means that you can select the dedicated standard from our database, and the Random test profile will be entered automatically.

Figure 5 - Test Templates in TestUp

Advanced Random Test Features

Sometimes test procedures require more advanced functions than the basic Random test. The functionality of Random in RULA software is extended beyond the basic parameters, and we can offer a number of options to considerably improve test experience and results, such as:

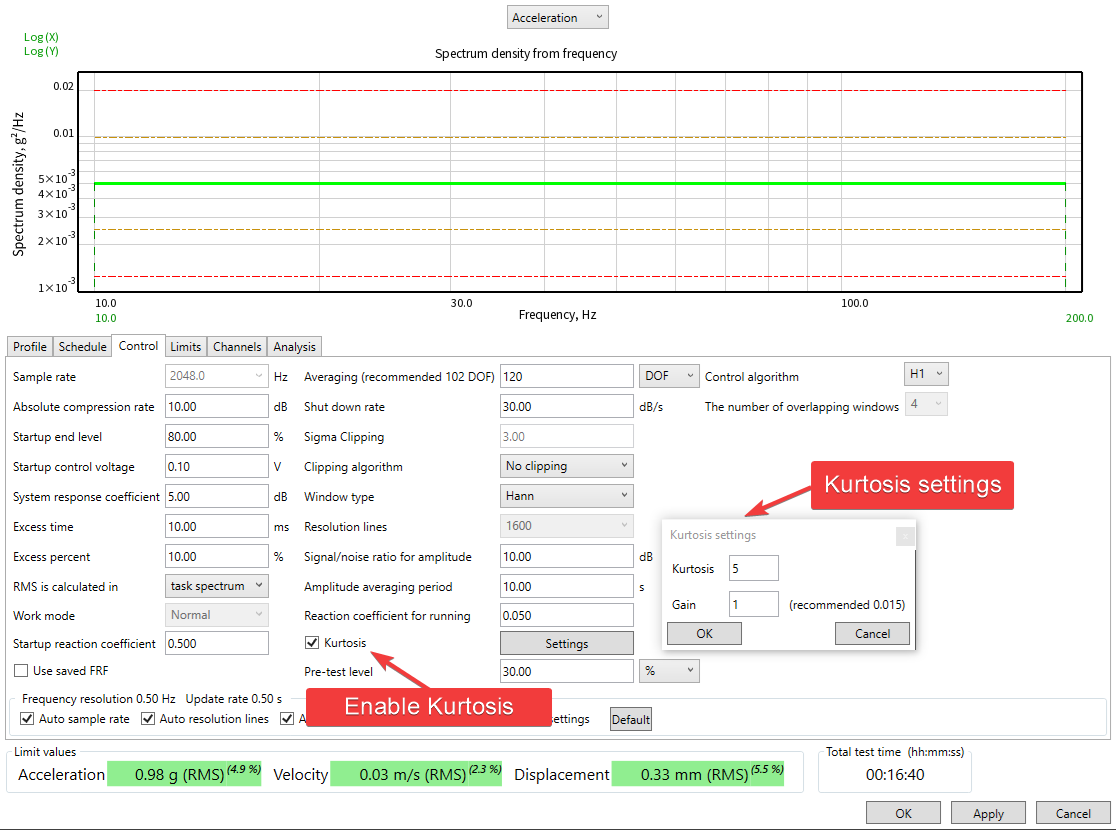

- Kurtosis: you can use a special checkbox in the Random test profile to specify the level of the steepness of the random spectrum peaks. By adjusting this level you can either make sure the vibration impact does not damage the structure, or you can amp the level up and subject the DUT to vibration levels closer to real-life random peak values. To learn more, read our article “What is Kurtosis”.

Figure 6 - Kurtosis settings in Test Up software for vibration testing

- Notching control is another way to limit PSD values. With this method, the user can apply high-level and low-level limiting and enter the particular PSD values in such a way that the signal cannot go above or below. For more information, please see more in our article “Notching Control and Why You Should Use it”.

Figure 7 - Example of test profile with Notching Limits in place

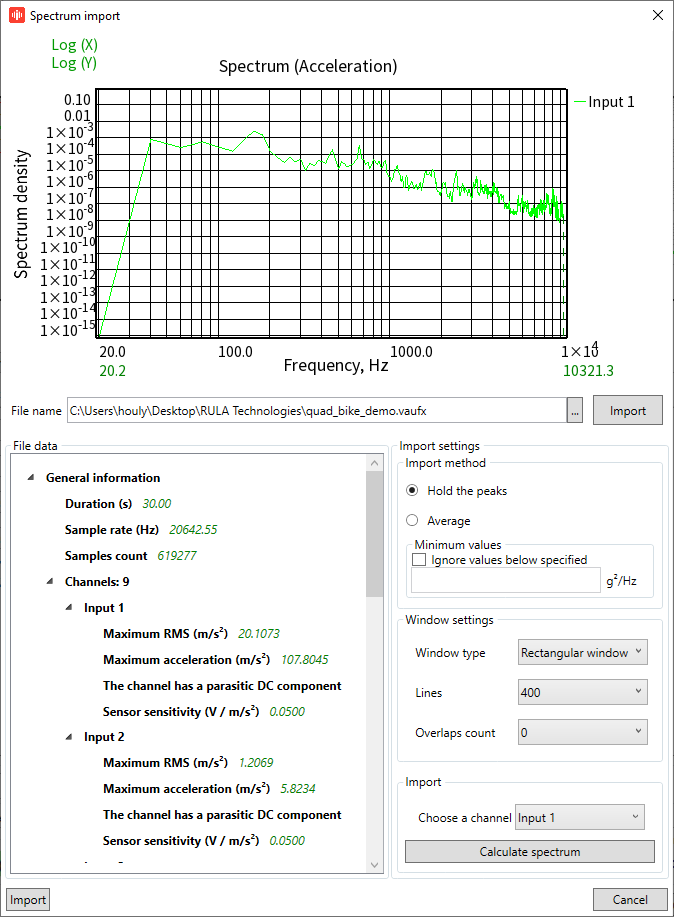

- Spectrum import is a feature of the Random test, which allows the user to create a random spectrum with the same vibration impact on the DUT as the signal from an uploaded recording. In order to create such a spectrum, the user should select a recording, specify the desired spectrum parameters and create a spectrum graph. After that, the software will generate the Random test profile, which will replicate the same spectrum graph. Read more about this feature in our article “6 Steps to Import Random Spectrum”

Figure 8 - Spectrum Import in TestUp

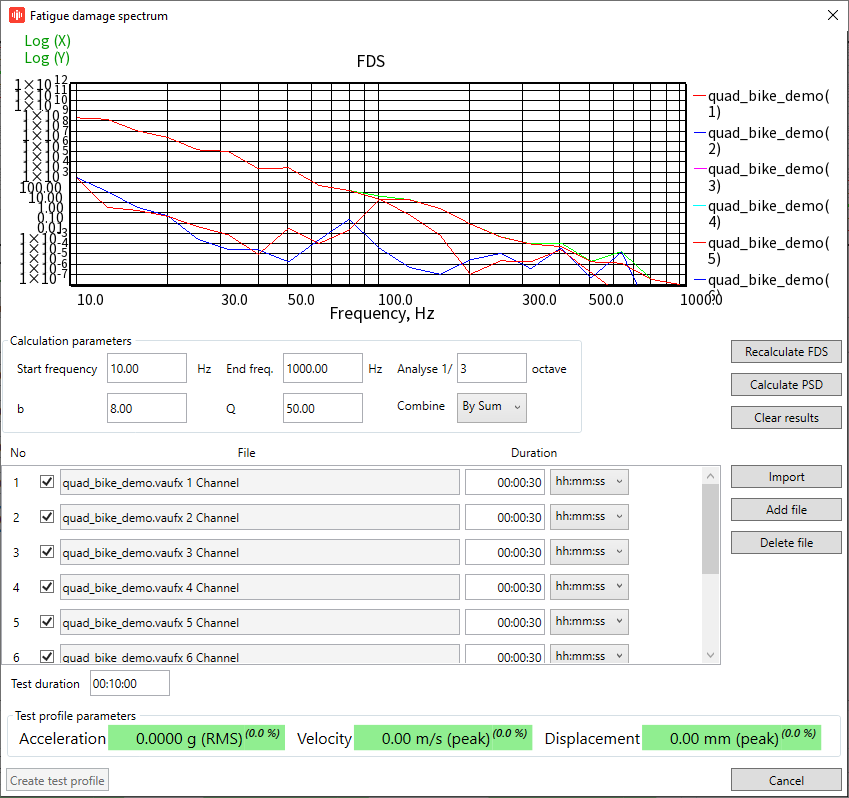

- Fatigue damage spectrum or FDS is a research-focused method derived from PSD that provides insights into the potential cumulative fatigue damage induced by random vibrations at different frequencies. FDS combines the advantages of Field Data Replication and Spectrum Import with the ability to combine multiple data files and manipulate the duration and level of fatigue damage to the structure. You can read more about FDS, its advantages, and related formulas in our article: “What is Fatigue Damage Spectrum?”.

Figure 9 - Fatigue Damage Spectrum module of TestUp

- CDoF is an advanced control tool, which can be selected in the default settings of TestUp software. The CDoF feature is an averaging algorithm that allows for faster spectrum averaging in the course of Random tests and, therefore, speeds up and optimizes the test process.

In addition to the listed Random test features, you might want to explore the capabilities of superimposed tests - SRoR (Sine-on-Random, Random-on-Random, Sine, and Random-on-Random). In this case, we deal with Sine tones or Random bands superimposed over the base Random spectrum. To learn the details, specifics, pros, and cons of superimposed tests, please follow our next articles.

Pros and Cons of Random Vibration Testing

Pros:

- Realistic simulation: Random vibration testing replicates the complex vibration patterns observed in real-world scenarios, ensuring an accurate assessment of a product's behavior.

- Detecting weak points: By subjecting a device to a wide range of frequencies, random vibration testing helps identify potential weaknesses and vulnerabilities that may not be apparent under steady-state or harmonic vibrations.

- Reliability evaluation: This testing method provides valuable insights into a product's resistance to environmental factors, such as shocks, vibrations, and temperature fluctuations.

Cons:

- Time-consuming: Random vibration testing typically requires longer test durations compared to traditional sinusoidal or harmonic testing methods due to the broader spectrum of frequencies. In contrast, sine testing, which focuses on specific frequencies, can be more time-efficient for pinpointing resonant frequencies but may not capture the full range of real-world vibrations experienced by the product. Therefore, engineers need to carefully consider the trade-off between time efficiency and capturing comprehensive data during testing.

- Complex data analysis: Analyzing the data collected from random vibration testing can be challenging, as it involves processing large amounts of information and interpreting statistical parameters.

- Decreased Repeatability: since this test in question is random in nature, it may be difficult to provide reproducibility of results in the test of serial production.

Conclusions

Random vibration testing plays a vital role in ensuring the reliability, durability, and performance of products across various industries. Understanding the pros and cons, international standards, testing tips, and setup considerations will enable engineers to conduct effective random vibration testing, improve product quality to increase product reliability, and guarantee long-term customer satisfaction.