As a first step, we’d like to classify all available shaker types, describe their applications and highlight their strong and weak points.

All shakers can be roughly divided into 4 types:

- Electrodynamic shakers,

- Servo-hydraulic shakers,

- Modal shakers,

- Shock- and drop-machines

ELECTRODYNAMIC SHAKERS

Electrodynamic shakers are widely used for all types of vibration tests, which have mid- and high frequencies and low displacement. Such tests are Sine, Random, and their variations (non-shock tests).

The operation of electrodynamic shakers is based on coil movement in the magnetic field. These shakers provide a wide frequency range, but in the majority of cases they cannot test extra-large and heavy loads.

Electrodynamic shakers may require a wide range of complementary equipment, such as slip tables, pneumatic systems to support the shakers table, fixtures, etc. Such accessories may help to increase the maximum load mass.

Another important feature of electrodynamic shakers is their potential capability to integrate with climate chambers, in order to run vibration and climatic tests simultaneously. For example, RULA RL-C21M system provides a capacity to integrate with a climate chamber using ModBus TCP protocol. Read more.

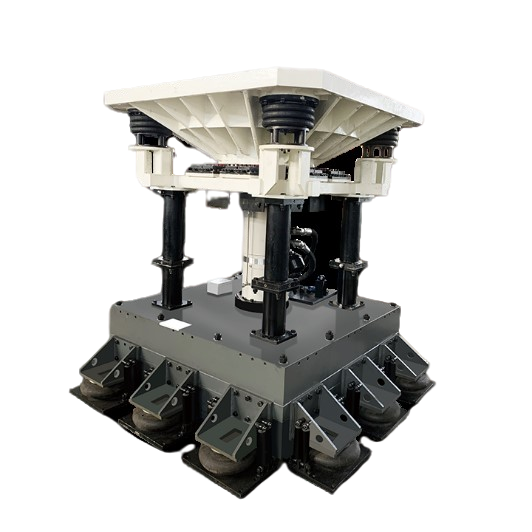

SERVO-HYDRAULIC SHAKERS

A servo-hydraulic shaker usually comprises one or more hydraulic actuators. Such shakers can handle huge load masses, but they are limited in test type selection (mainly, to Sine and Random) and the frequency range is usually not more than 500 Hz.

RULA has a number of successful customer case of working with servo-hydraulic shakers.

MODAL SHAKERS

Modal shakers are used to study the vibration behaviour of structures.

These shakers are attached to the structure with a stinger and the force is transferred from the shaker to the structure via this stinger. The structure under test and the modal shaker can be suspended during the test using components such as an elastic rope or spring to simulate free-free boundary conditions. In this way it is possible to excite the DUT at different frequencies.

As a result, the natural frequencies and mode shapes of the structure can be calculated from the vibration values measured in the structure.

Modal shakers usually have a built-in amplifier.

As you can see, this type of shakers is quite specific. However, RULA supports the use of modal shakers both with our vibration controllers and software.

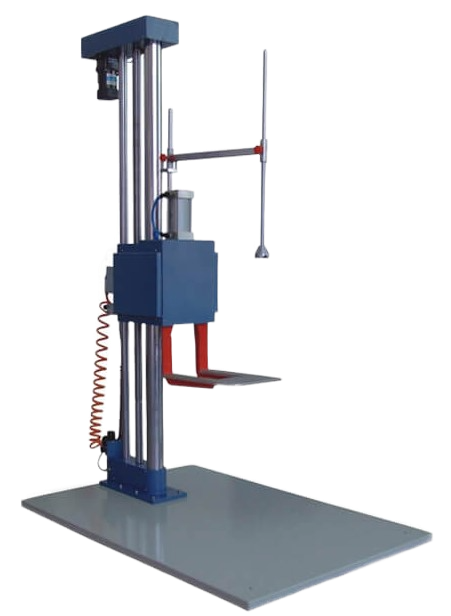

SHOCK-AND-DROP MACHINES

Drop machines are used during Transient capture test, when we need to analyze the drop impact on testing objects. Shock machines can perform high amplitude shocks on your DUT without damaging it. Using a drop machine, you can place multiple sensors on your object-under-test, drop it and analyze the captured shocks.

RULA systems successfully work with shock- and drop-machines in Transient Capture mode.

KEY SHAKER PARAMETERS

During the shaker selection and its subsequent use, it is important to remember about several key characteristics:

- Maximum moving force

This parameter is calculated using the formula F = ma.

In this case “m” is the mass of the slip table and, the load and all fixtures, “a” is the maximum acceleration value for this mass and F is the maximum moving force value.

For example, the total mass of DUT, slip table and sensors is 100 kg, the test has the maximum acceleration value of 100 G. In that case we need a shaker with a force value of 10000 N. As the force value is fixed, you should remember that in case of increasing the load mass, you will need to decrease the maximum acceleration value.

- FRF – the frequency response function of the shaker

- Maximum acceleration, velocity and displacement values.

All the values listed above are given in the shaker technical documentation, so it is important to refer to it before purchase and as you set up your vibration test.

As you select the shaker, you will also need to compare the permissible frequency range of the shaker and you test specification. For example, for a Sine test run in the frequencies between 5 Hz up to 1000 Hz, you cannot apply a shaker with 10 Hz start frequency, as it may damage the shaker.

SHAKER PLACEMENT

If you are going to test massive objects, you should have a dedicated foundation for the lab or the part, where the shaker is housed. The mass of the foundation must be approximately 10 times bigger than the mass of the shaker and the object under test together. It is important that this dedicated foundation is not connected to the main foundation of the building.

The shaker should not be placed against the wall, so is to have access to the shaker from all the sides. It will help you to check or fix the shaker, replace the equipment, change sensors, etc.

If your lab space permits, it is always good to isolate the test room from the operator’s room to make sure the engineer is safe and comfortable.

In some cases, your shaker may need to have a cooling system. In this case, placing it in the isolated test space may be a good idea, so that the vibrations from the cooling system do not interfere with your test process.

Last but not least, one should take care of the safe and reliable power supply and grounding.

A few words about accessories and fixtures.

Sometimes you cannot place your DUT directly on the shaker without any external fixture. In this case, the customer is supplied with some kind of a slip table, which accommodate the size of the DUT.

The general principle of DUT mounting is to try to place the object under test as close to the center of the slip table as you can. Placing it otherwise may lead to the shaker dropping over. So if it is not possible to place your object in a such way, you should use an extended shakers table. If your object is big, it is recommended to have a cathead.

ADDITIONAL CONSIDERATION

1) We recommend using the shaker at the maximum 70% of its capacity to guarantee the shakers long and smooth operation. This should be taken into account when choosing the shaker.

2) Mind the resonant frequencies of the shaker and fixtures as you select and set up your vibration test equipment.

ARTICLE SUMMARY

To sum up everything above, we list the most crucial characteristics you need to consider when choosing a shaker:

- Vibration Test Parameters (Max values, frequencies, number of Axis)

- Object under test (Mass, size, type of DUT)

- Fixture (fixture type, additional equipment)

- Test room characteristics (grounding, power supply, size, noise isolation, access to the shaker)

- Way of testing (regular vibration tests, modal analysis and research, shock and drop tests)

RULA systems automatically save and calculate the crucial shaker parameters to ensure the maximum safety and ease of vibration tests. Read more.

If you need assistance in choosing a shaker and a vibration controller, please contact us at contact@rula-tech.com, and we will help you through the process.