Sign up

Fill in the fields and send the application for registration. Your application will be reviewed as soon as possible.

If you already have an account, please sign in, or restore your password.

Sign in

To log in, fill in the fields below.

And have a good day.

If you do not have an account, please sign up, or restore your password

Restore password

To reset your password, fill in the field below. After that, you will be notified in the email.

If you do not have an account, please sing up, or sign in if you have one.

Solution

RULA technologies have created a specialized calibration software module, which can be used together with RL-C21 vibration control system.

What is an accelerometer

- The sensor performs according to its specifications;

- The sensor is still «healthy».

Calibration standards

- ISO 16063-1:1998 Methods for the calibration of vibration and shock transducers — Part 1: Basic concepts

- ISO 16063-12:2002 Methods for the calibration of vibration and shock transducers — Part 12: Primary vibration calibration by the reciprocity method

- ISO 16063-21:2003 Methods for the calibration of vibration and shock transducers — Part 21: Vibration calibration by comparison to a reference transducer

- ISO 16063-31:2009 Methods for the calibration of vibration and shock transducers — Part 31: Testing of transverse vibration sensitivity.

Calibration Equipment

- a reference transducer;

- a shaker with a power amplifier;

- a specialized controller with precise input and output channels;

- a PC with calibration software.

The typical calibration set is shown in the picture. It includes a reference sensor mounted on the shaker, a shaker and an amplifier.

If the sensor under calibration is mounted directly on the reference sensor, such a procedure is called back-to-back calibration.

Calibration Procedure

- Reference sensitivity measurements. During the operation, we determine the sensitivity on the reference frequency (usually 160 or 200 Hz);

- Frequency response measurements. During the operation, we determine the sensitivity on all the frequencies of the sensors frequency range.

Measurements

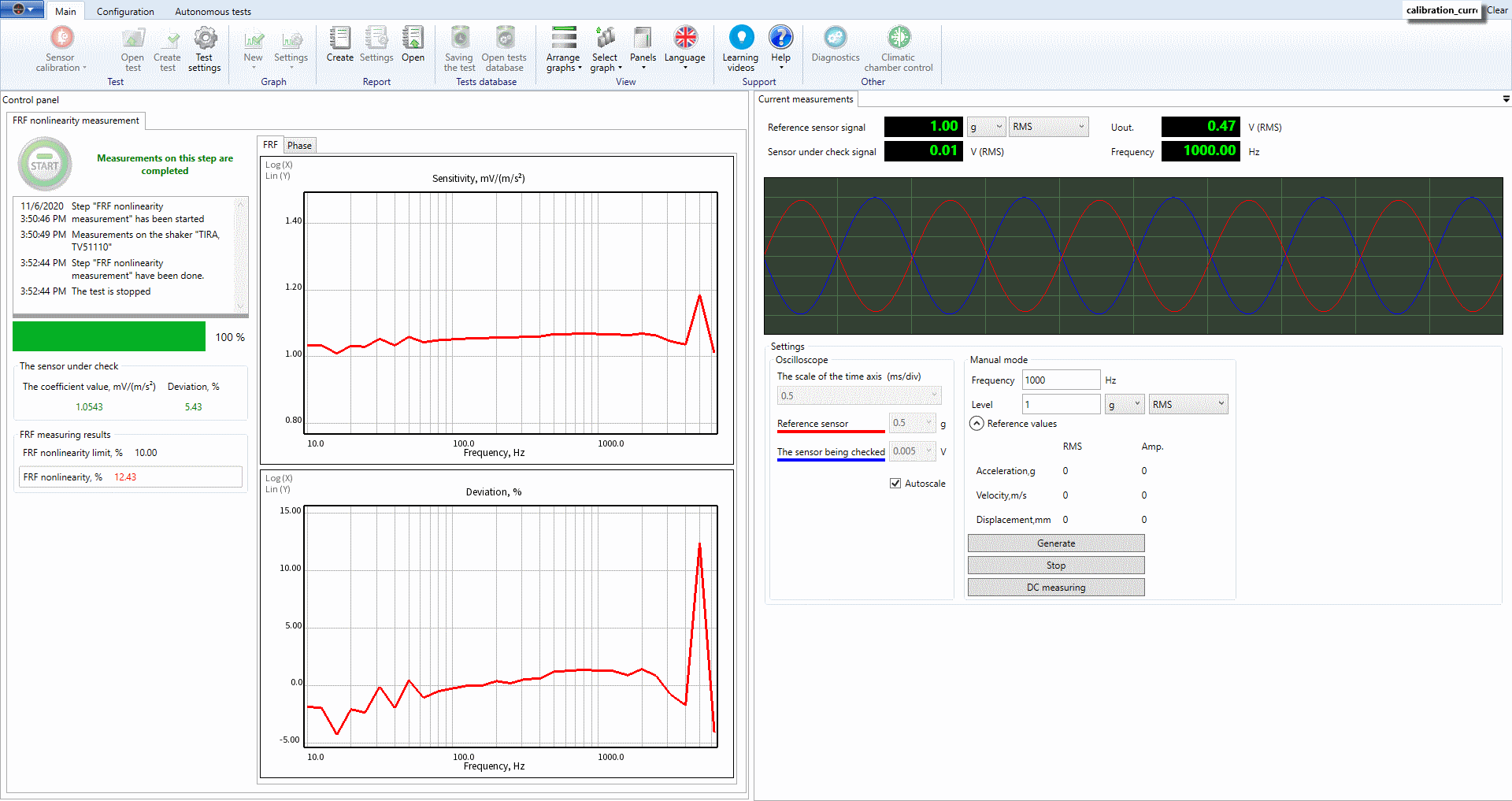

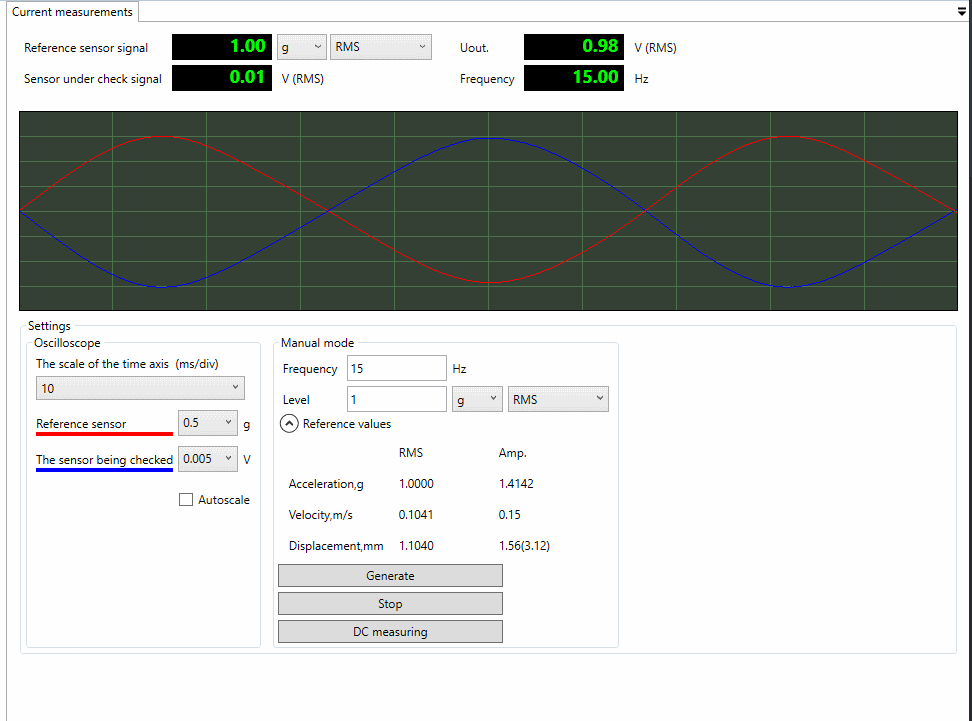

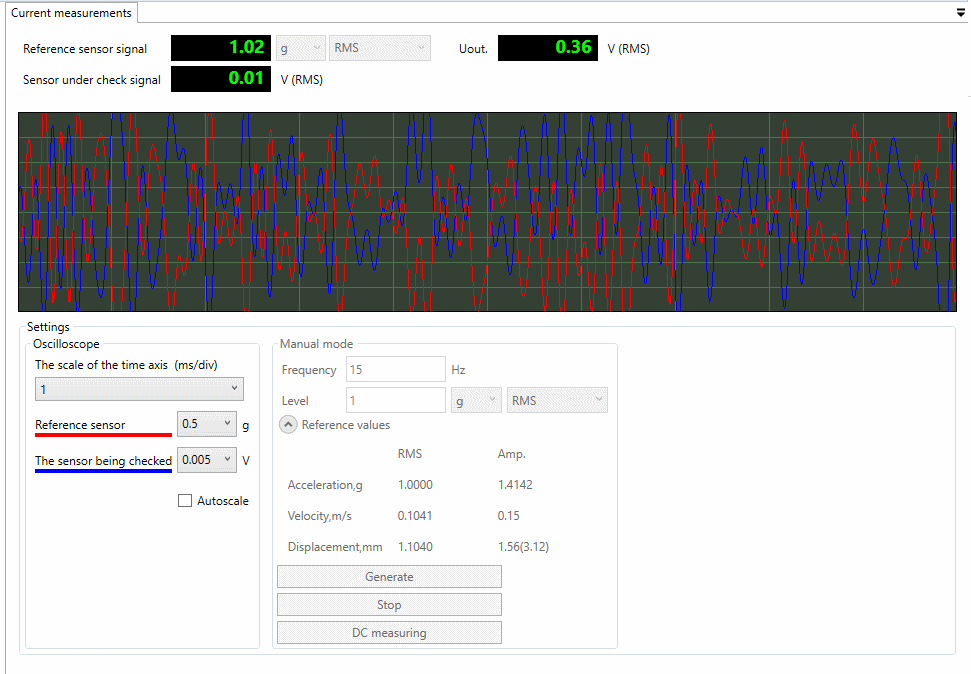

Usually, a sine wave is used to excite both sensors.

When the sine wave is being generated on the shaker, the output signals of the reference sensor and sensor under calibration are measured.

After that, sensitivity is calculated by the formula:

|

Sc – sensitivity of the sensor under calibration; |

The procedure repeats itself on five or six frequencies distributed through the frequency range of the sensor under calibration, one frequency is the minimum, one the maximum and one the reference frequency of the accelerometer.

Faster calibration

In spite of the fact that with RULA equipment all the excitations and calculations are carried out automatically, without any input from the user, sine excitation procedure takes long time.

Therefore, in addition to sine wave excitation, TestUp software provides calibration with Random signal excitation. In this case, the shaker is excited with a random signal, which contains all the frequencies in the sensor frequency range. If a random signal is used, sensitivities on all the frequencies are measured simultaneously. This way reduces the calibration time to three or four minutes.

Better accuracy

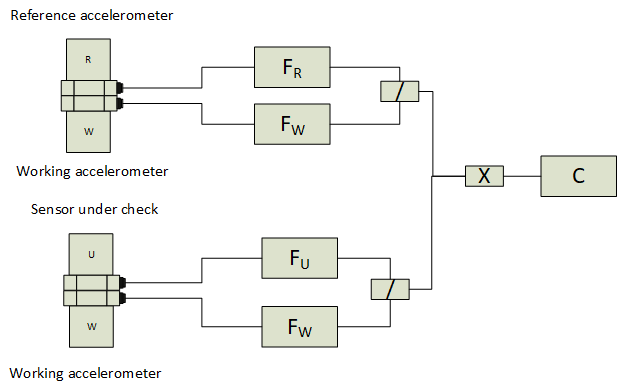

Traditional back-to back calibration can be inaccurate if the sensor under calibration is bigger or heavier than the reference sensor. The error grows with the increase of frequency. To avoid such an error, in TestUp software we implemented the procedure of calibration by substitution.

Besides correcting the errors caused by the sensor mass and sizes, calibration by substitution eliminates the errors caused by the non-linearity of measurement channels and reduces the uncertainty of measurements.

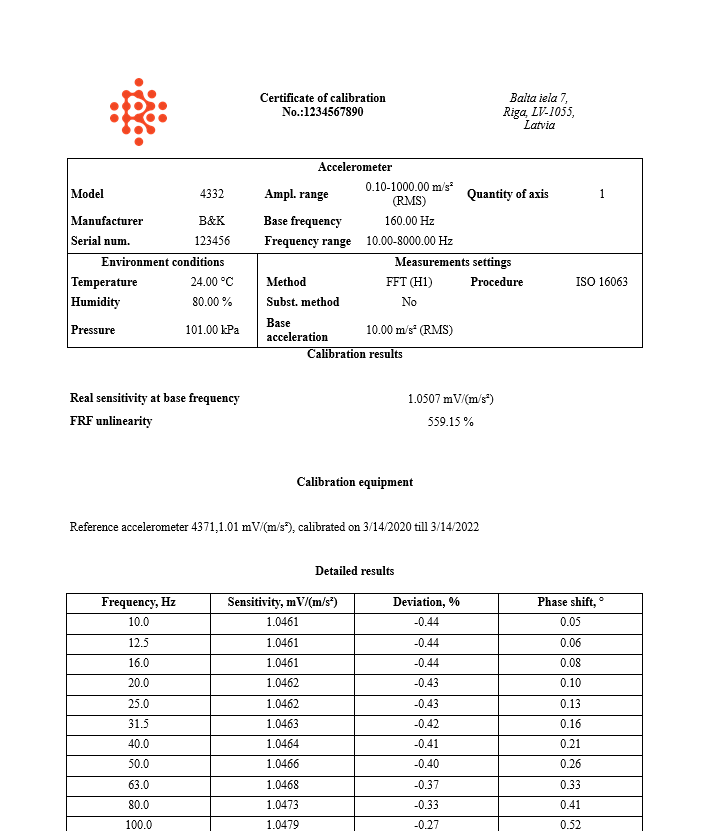

Creating reports

After any calibration, TestUp automatically creates a comprehensive report, which includes:

- measurement results in the form of tables and graphs;

- detailed information about the reference sensor;

- calibration date and place, etc.

Research and development

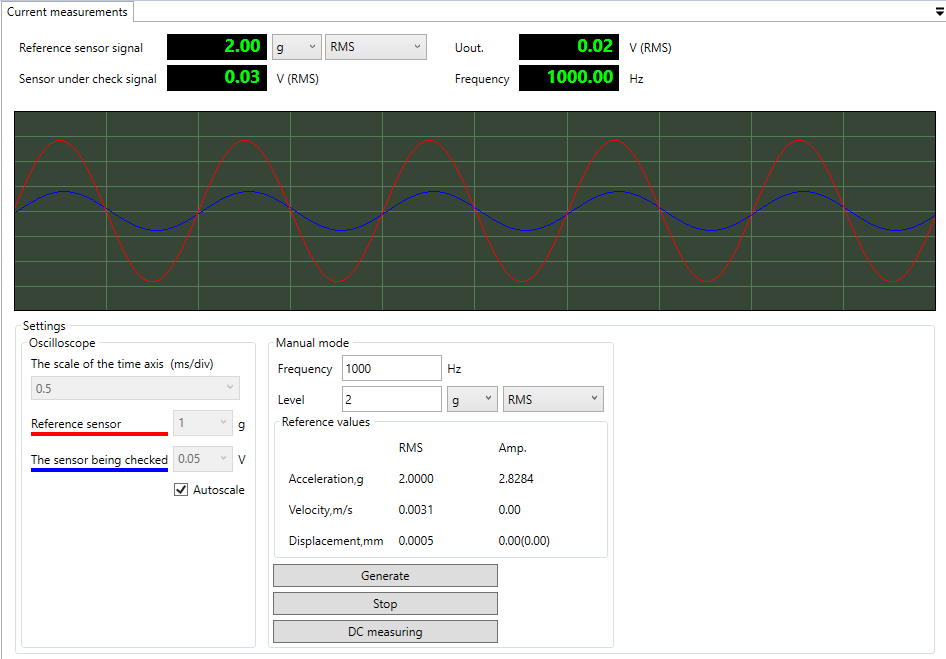

Besides the automated measurements, a manual measurement mode is implemented in TestUp.

The mode allows specifying the frequency and amplitude (in acceleration, velocity or displacement units) manually and checking the response from the sensors. The mode is highly useful for research purposes.

Innovative, yet easy-to-use software

RULA Technologies have developed an extensive subsystem of vibration transducer calibration.

It is an innovative, yet easy-to-use software, which provides automated calibration of a wide range of vibration sensors. The system uses a range of calibration methods, innovative and well-established, according to ISO 16063-21.

Our advantages are:

- Compliance with international standards;

- Innovative calibration methods;

- Short calibration time;

- Easy intuitive interface;

- Comprehensive reports.

Submit your request

Do you have questions or suggestions about our products? Fill out the form and you are one step closer to the answer.Privacy policy

Welcome to our Privacy Policy

Your privacy is critically important to us.

RULA Technologies is located at:

Balta iela 7, Riga, LV-1055, Latvia

It is RULA Technologies's policy to respect your privacy regarding any information we may collect while operating our website. This Privacy Policy applies to https://rula-tech.com (hereinafter, "us", "we", or "https://rula-tech.com"). We respect your privacy and are committed to protecting personally identifiable information you may provide us through the Website. We have adopted this privacy policy ("Privacy Policy") to explain what information may be collected on our Website, how we use this information, and under what circumstances we may disclose the information to third parties. This Privacy Policy applies only to information we collect through the Website and does not apply to our collection of information from other sources.

Depending on your activities when visiting our Website, you may be required to agree to additional terms and conditions.

- Website Visitors

Like most website operators, RULA Technologies collects non-personally-identifying information of the sort that web browsers and servers typically make available, such as the browser type, language preference, referring site, and the date and time of each visitor request. RULA Technologies's purpose in collecting non-personally identifying information is to better understand how RULA Technologies's visitors use its website. From time to time, RULA Technologies may release non-personally-identifying information in the aggregate, e.g., by publishing a report on trends in the usage of its website.

RULA Technologies also collects potentially personally-identifying information like Internet Protocol (IP) addresses for logged in users and for users leaving comments on https://rula-tech.com. RULA Technologies only discloses logged in user and commenter IP addresses under the same circumstances that it uses and discloses personally-identifying information as described below.

- Gathering of Personally-Identifying Information

Certain visitors to RULA Technologies's websites choose to interact with RULA Technologies in ways that require RULA Technologies to gather personally-identifying information. The amount and type of information that RULA Technologies gathers depends on the nature of the interaction. For example, we ask visitors who sign up at https://rula-tech.com to provide a username and email address

- Security

The security of your Personal Information is important to us, but remember that no method of transmission over the Internet, or method of electronic storage is 100% secure. While we strive to use commercially acceptable means to protect your Personal Information, we cannot guarantee its absolute security.

- Links To External Sites

Our Service may contain links to external sites that are not operated by us. If you click on a third party link, you will be directed to that third party's site. We strongly advise you to review the Privacy Policy and terms and conditions of every site you visit.

We have no control over, and assume no responsibility for the content, privacy policies or practices of any third party sites, products or services.

- Protection of Certain Personally-Identifying Information

RULA Technologies discloses potentially personally-identifying and personally-identifying information only to those of its employees, contractors and affiliated organizations that (i) need to know that information in order to process it on RULA Technologies's behalf or to provide services available at RULA Technologies's website, and (ii) that have agreed not to disclose it to others. Some of those employees, contractors and affiliated organizations may be located outside of your home country; by using RULA Technologies's website, you consent to the transfer of such information to them. RULA Technologies will not rent or sell potentially personally-identifying and personally-identifying information to anyone. Other than to its employees, contractors and affiliated organizations, as described above, RULA Technologies discloses potentially personally-identifying and personally-identifying information only in response to a subpoena, court order or other governmental request, or when RULA Technologies believes in good faith that disclosure is reasonably necessary to protect the property or rights of RULA Technologies, third parties or the public at large.

If you are a registered user of https://rula-tech.com and have supplied your email address, RULA Technologies may occasionally send you an email to tell you about new features, solicit your feedback, or just keep you up to date with what's going on with RULA Technologies and our products. We primarily use our News page to communicate this type of information, so we expect to keep this type of email to a minimum. If you send us a request (for example via a support email or via one of our feedback mechanisms), we reserve the right to publish it in order to help us clarify or respond to your request or to help us support other users. RULA Technologies takes all measures reasonably necessary to protect against the unauthorized access, use, alteration or destruction of potentially personally-identifying and personally-identifying information.

- Aggregated Statistics

RULA Technologies may collect statistics about the behavior of visitors to its website. RULA Technologies may display this information publicly or provide it to others. However, RULA Technologies does not disclose your personally-identifying information.

- Cookies

To enrich and perfect your online experience, RULA Technologies uses "Cookies", similar technologies and services provided by others to display personalized content, appropriate advertising and store your preferences on your computer.

A cookie is a string of information that a website stores on a visitor's computer, and that the visitor's browser provides to the website each time the visitor returns. RULA Technologies uses cookies to help RULA Technologies identify and track visitors, their usage of https://rula-tech.com, and their website access preferences. RULA Technologies visitors who do not wish to have cookies placed on their computers should set their browsers to refuse cookies before using RULA Technologies's websites, with the drawback that certain features of RULA Technologies's websites may not function properly without the aid of cookies.

By continuing to navigate our website without changing your cookie settings, you hereby acknowledge and agree to RULA Technologies's use of cookies.

Privacy Policy Changes

Although most changes are likely to be minor, RULA Technologies may change its Privacy Policy from time to time, and in RULA Technologies's sole discretion. RULA Technologies encourages visitors to frequently check this page for any changes to its Privacy Policy. Your continued use of this site after any change in this Privacy Policy will constitute your acceptance of such change.

- Processing Policy

- Credit & Contact Information

This privacy policy was created at https://termsandconditionstemplate.com/privacy-policy-generator/.

If you have any questions about this Privacy Policy, please contact us via email or phone.