The focus of Sine vibration testing is to see how the object performs under constant vibration in a safe environment of a testing laboratory. A Sine vibration test exposes the object or structure to a Sine tone at a defined amplitude and frequency.

The reason behind the prevalence of Sine vibration testing is the fundamental nature of the Sine wave. This is the wave type of AC current, RF or radio frequency, audio test signals, and many naturally occurring vibrations. A pure Sine wave is free of harmonics, with its energy confined to a single frequency.

Why choose Sine test?

- Simplicity. Sine test is considered to be one of the simplest and therefore most reliable vibration tests.

- Visual clarity and accuracy. Sine vibration test sweeps through the user-set profile one frequency at a point, therefore reaching higher Signal-to-Noise ratio and producing clean response. This makes Sine vibration testing one of the best ways to identify resonance frequencies of the test object.

- Focused approach. Sine vibration dwell is an effective way to test endurance and durability of a structure on its natural resonance frequencies.

Sine vibration testing is used in a large variety of fields: robotics, calibration and certification, battery testing, logistics, automotive, and many others.

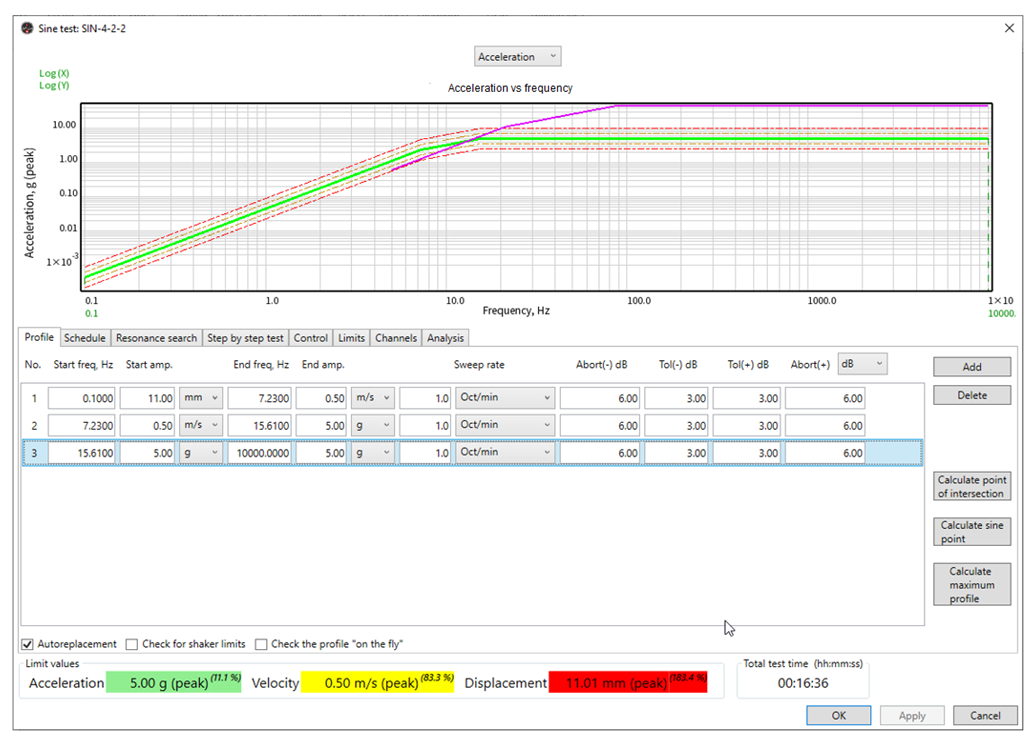

A Sine vibration test operates with the following parameters:

- Amplitude (in g, mm, m/s)

- Frequency (in Hz)

- Duration (in values of time)

- Sweep rate

Figure 1: Sine vibration profile window in RULA software

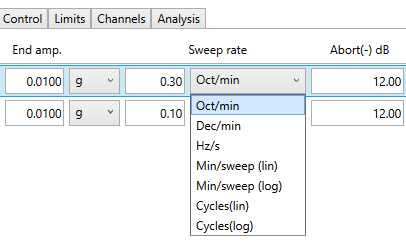

Normally, Sine signal sweeps at a set rate (interval per bandwidth) in octaves per minute or other values such as Hertz.

Figure 2: Sweep rate settings of Sine vibration profile in RULA software

Engineers can get necessary Sine Vibration parameters from field measurements or national standards such as MIL-STD-810, DO-160, ISO-16063, IEC-60068, and others.

Sine Vibration tests can be separated into three main types:

- Sine Dwell

- Sine Sweep

- Resonance Search

All three types of SV can be run in a sequence depending on the task. First, engineers run a Sine sweep test to expose the test object to sine tone on a set frequency range. This helps determine the resonant frequencies of the object. Next, Sine dwell is used to establish, how long the object survives under constant exposure to vibration on its natural resonance frequencies to ensure its safety in the real-life conditions.

Now let’s talk about each type in more detail.

1. Sine Dwell

Sine Dwell is the purest form of Sine vibration testing, with a Sine wave applied to the test object at a constant rate.

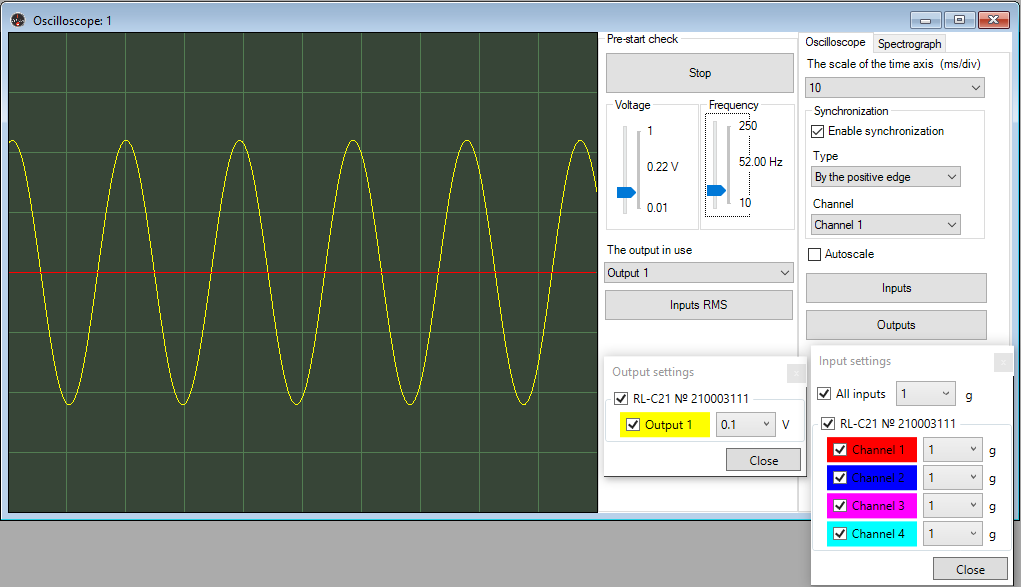

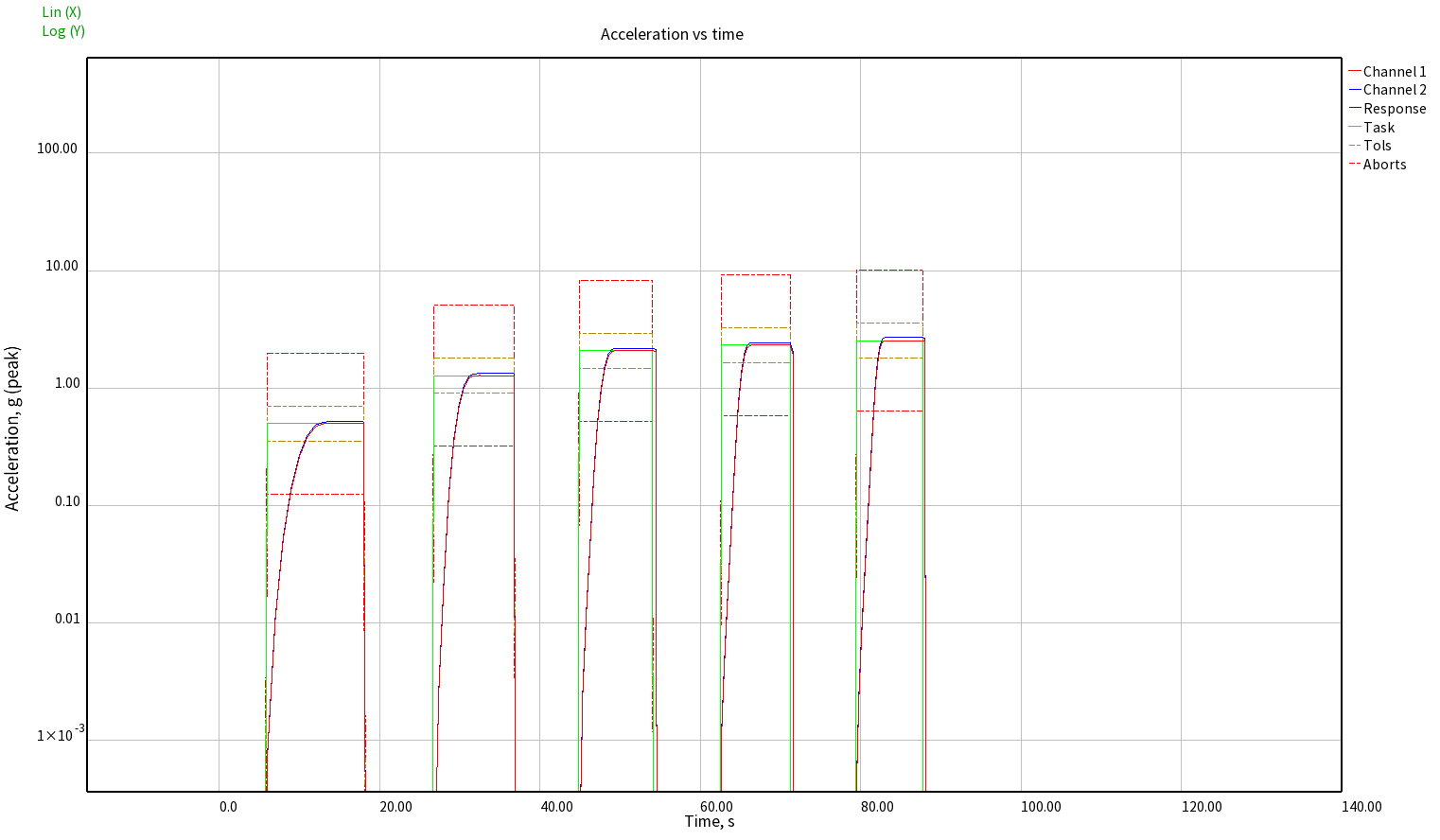

The only parameters required for Sine dwell test are vibration amplitude, frequency and duration. In RULA software, you can define amplitude in values of acceleration (g), velocity or displacement.

Figure 3: Sine dwell in the Pre-test diagnostics mode of RULA software

2. Sine Sweep

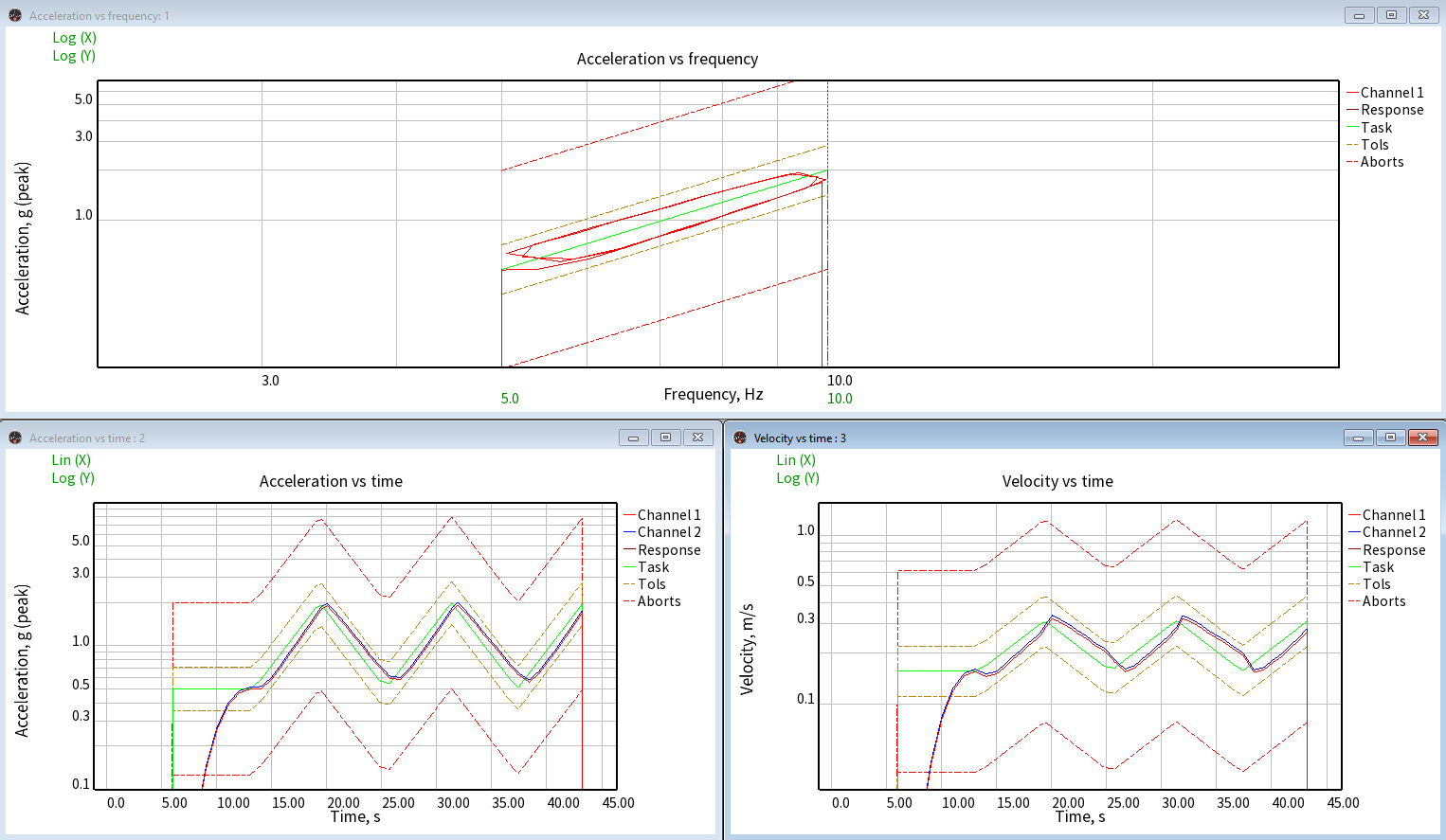

With Sine sweep, the values of amplitude and frequency of a Sine wave gradually change at a set sweep rate following the points of the profile. This change forms a tracking curve that will be displayed in the vibration control software. The addition of a curve makes it easier to compare the actual vibration amplitude with that of the set target.

Figure 3: Multiple Sine sweeps displayed on the graphs

One of the subtypes of Sine Sweep is stepped Sine where the frequency is increasing in a step-like fashion with user-set interval between each step.

Figure 4: Stepped Sine profile in RULA software

To ensure that the test is safely within the shaker limits, the software also displays the maximum peak values of acceleration, velocity and maximum peak-peak values of displacement alongside shaker capabilities. The deviation from the curve is limited by two thresholds: normally, ±3 dB and ±6 dB. If the amplitude exceeds the second level, the test is automatically aborted to prevent equipment damage.

Contrary to the clean Sine tone we use to drive the shaker, a signal measured at the test object will contain harmonics and noise. To get rid of them, we apply a number of low-pass and high-pass dynamic filters to the signal.

3. Resonance Search and Dwell (RSTD)

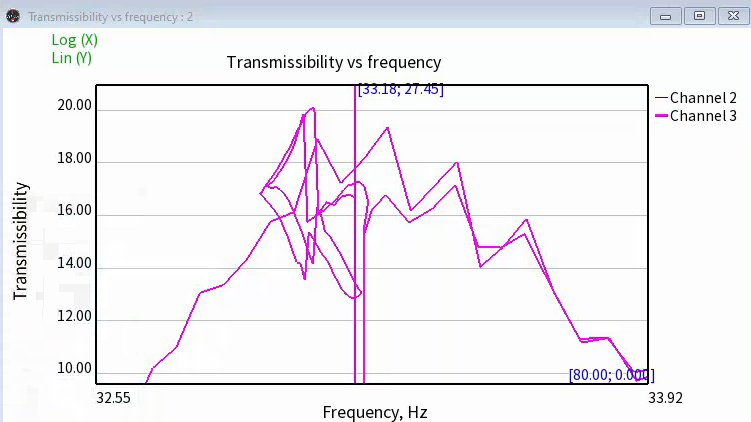

A simple Sine sweep test allows an engineer to quickly identify resonance frequencies of the test object or structure. High resonance peaks on certain frequencies help to find weak points of the test object. With this knowledge in mind, an engineer could design a Sine test to dwell on a resonance until the object is destroyed or until a certain test duration is reached to ensure the object survives the same exposure in a real-life scenario.

Figure 6: Resonance dwell and tracking in RULA software

Where else can we use Sine vibration?

- Shaker validation. Running a number of Sine tests and comparing the response is an effective way to check the health of the shaker system. Any significant troubles with construction will change the response values.

- Sensor calibration. Normally, a Sine wave is used to excite the sensors and determine their sensitivity on all frequencies of the target range. This method is reliable, but can be quite slow, especially on low frequencies. Transducer calibration module of RULA software allows you to use Random vibration to decrease calibration time to less than 4 minutes.

- Pre-start check (Diagnostics mode). Using a simple Sine without feedback helps determine that all parts of the system are connected correctly and are functioning.

What are the limitations of Sine vibration testing?

Even though Sine vibration testing is considered to be a staple method, it has its share of limitations:

- Low coverage. Testing an object with a Sine signal can only excite it on one frequency at a time, unless you are using a Fatigue testing module to dwell on multiple resonant frequencies.

- Long test duration. Testing an object with a complicated profile containing multiple cycles and sweeps might take a long time due.

- Artificial nature. A pure Sine wave contains no harmonics and can only excite one set frequency at a time, which makes it harder to simulate certain real-life vibrations that might occur during transportation, aircraft takeoff, etc.

The way to account for these weak points is to use Random vibration testing, which we will cover in our next article.

Need to perform Sine vibration testing in your factory or lab? Choose a vibration controller from our catalog and contact us for further information.