Field Data Replication (FDR) is a testing method that uses real data recorded from actual events to test how products behave under real-life events like explosions, road bumps, various transportation conditions, and types of shocks. Instead of relying on mathematical models or predictions, FDR plays back the exact vibrations or shocks a product would experience during its use. For example, if a vehicle experiences vibrations during a rough road trip, FDR can recreate those exact vibrations in a lab to test how the vehicle withstand the real-life conditions.

Field Data Replication (FDR) is a testing method that uses real data recorded from actual events to test how products behave under real-life events like explosions, road bumps, various transportation conditions, and types of shocks. Instead of relying on mathematical models or predictions, FDR plays back the exact vibrations or shocks a product would experience during its use. For example, if a vehicle experiences vibrations during a rough road trip, FDR can recreate those exact vibrations in a lab to test how the vehicle withstand the real-life conditions.

Comparing FDR to basic test types, there is a notable distinction. While Sine test type applies a generated periodic waveform, and Random test type utilizes a spectrum of varying frequency signals to simulate unpredictable environments, FDR directly reproduces the recorded responses from the field.

What are the application spheres of FDR test type?

The key application of FDR is in industries, where equipment durability under extreme conditions is vitally important, such as aerospace, automotive, railway. Real-life examples of FDR include:

- testing aviation components (wings, engines) by replicating vibrations experienced during flights;

- evaluating the reliability of train components (wheels, braking systems) by simulating the vibrations and shocks during rail travel;

- assessing vehicle components (shock absorbers, suspension systems) by replicating the vibrations and shocks experienced on rough roads and different terrains.

What products does RULA offer for data recording?

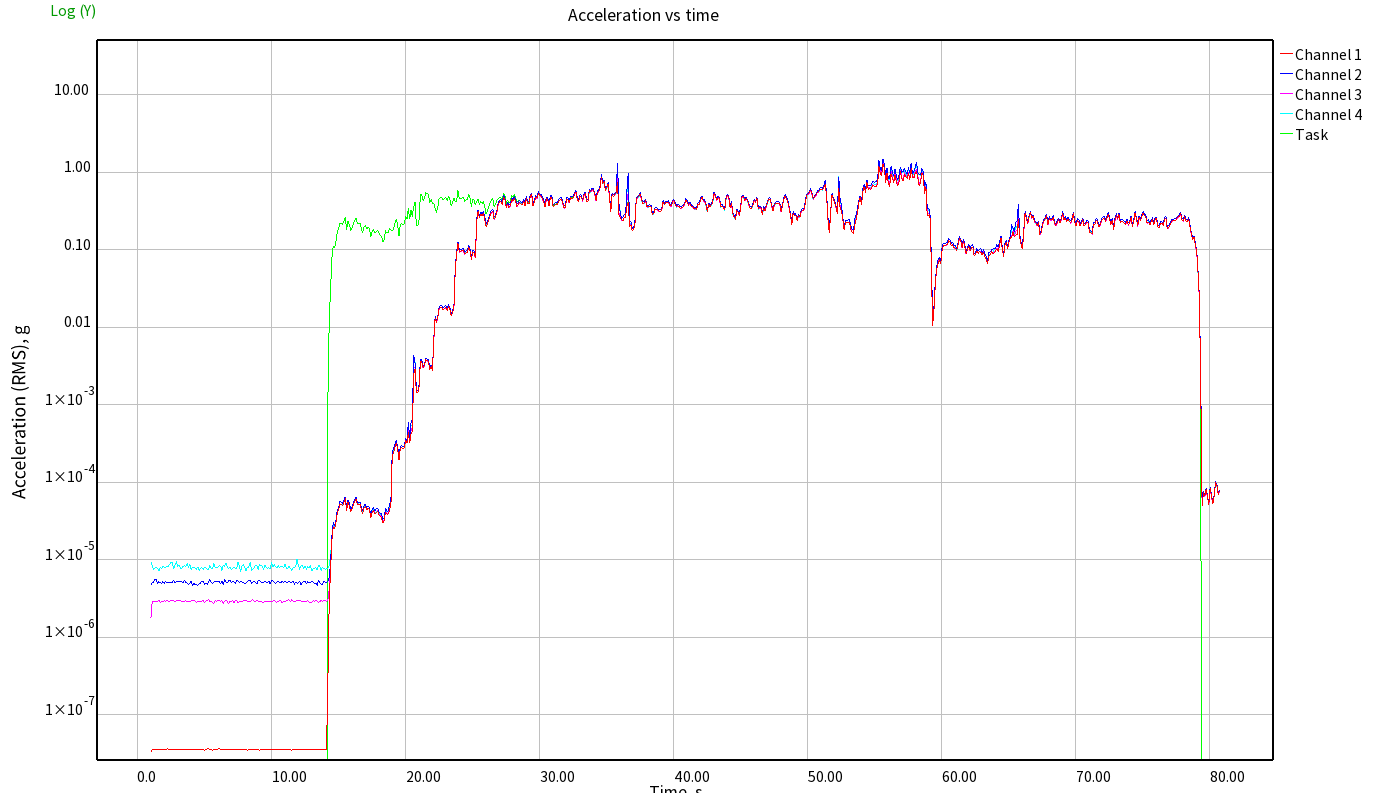

RULA offers a range of products for data recording, tailored to meet various needs. The RL-R19 can be mounted on vehicles or aircraft to record data from connected sensors, making it ideal for monitoring performance road or flight conditions. The RL-R17 can be placed on transportation containers, ensuring vibration data is captured throughout the shipping process. For more complex recording needs, the RL-C25 can be utilized in the lab to record multiple channels simultaneously. All of these systems record data in the proprietary RULA VAUFX format, however they are easily convertible to basic recording formats. To illustrate the recording capacities, watch the data recording process on RL-R19, where we captured data from three accelerometers; the final signal highlights the road vibrations experienced during a ride on a quad bike.

How to conduct FDR vibration test in TestUp?

In TestUp software, FDR vibration test is set up and run in a few simple steps, as you can see in the screenshots below.

Step 1. Select FDR test type.

For running FDR tests, we use a special file format - VAUFX, which represents a recorded accelerogram from the controller/recorder. TestUp has a built-in VAUFX file converter, and you can convert your audio, text and CSV tables into the desired file format. For the example of an FDR test, we use a recording of road shaking made by RL-R17.

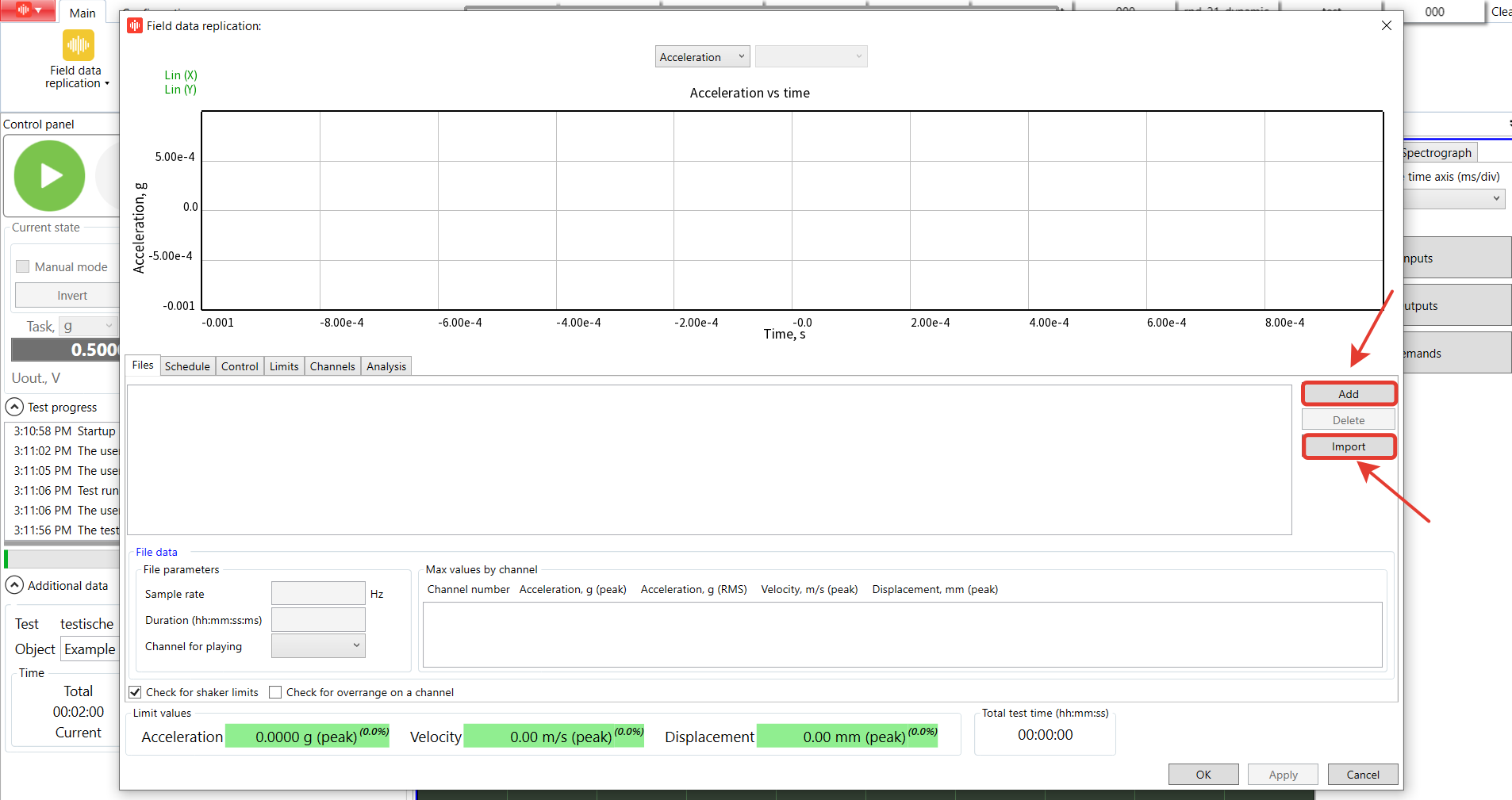

Step 2. Open «Files» tab and select a signal for replication. There are two ways of adding files:

- Click on “Add” button and select your VAUFX file;

- Click on the “Import” button and select a text or sound file. The file will be automatically converted into the VAUFX format.

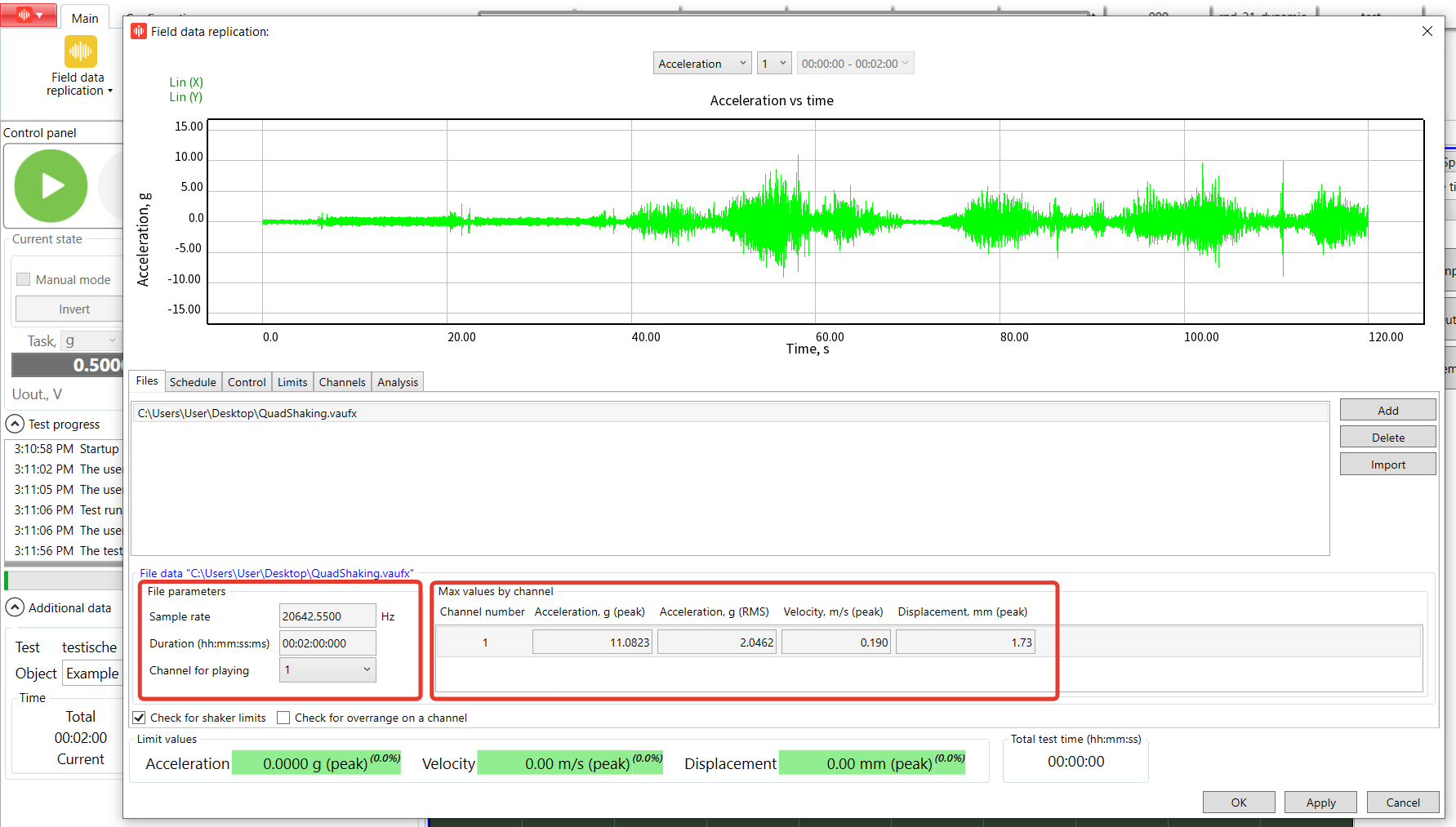

After you have selected the file, in the bottom of the tab, you will see the information about the file, its sample rate, duration, channel for playing, as well as max values for every recorded channel.

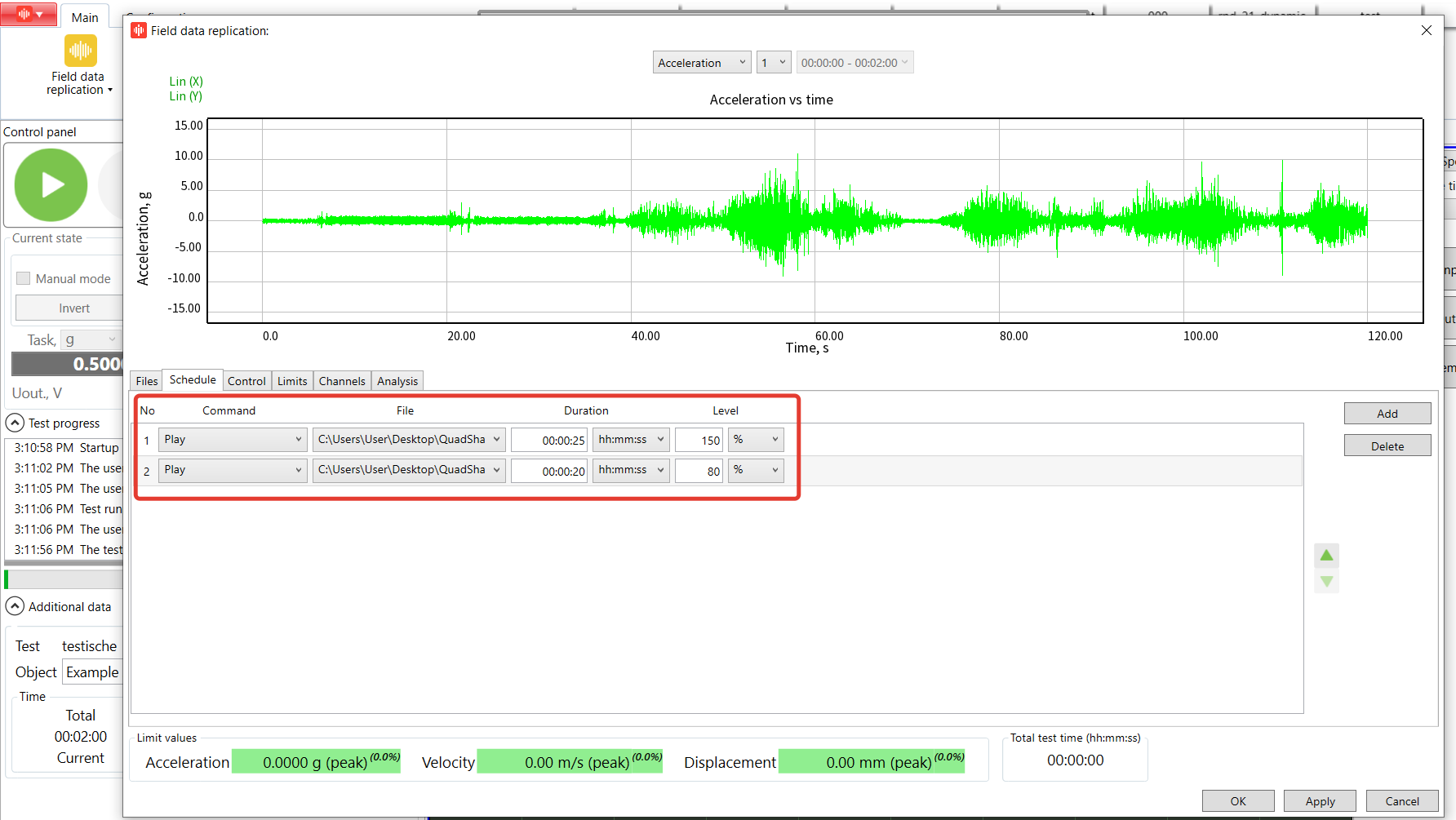

Step 3. Open the “Schedule” tab. Add the “Play” command to the schedule. Select the file and the desired time duration for the signal replication.

As you can have multiple files added to the test, you can add two “Play” commands and play two files one after another during the test run.

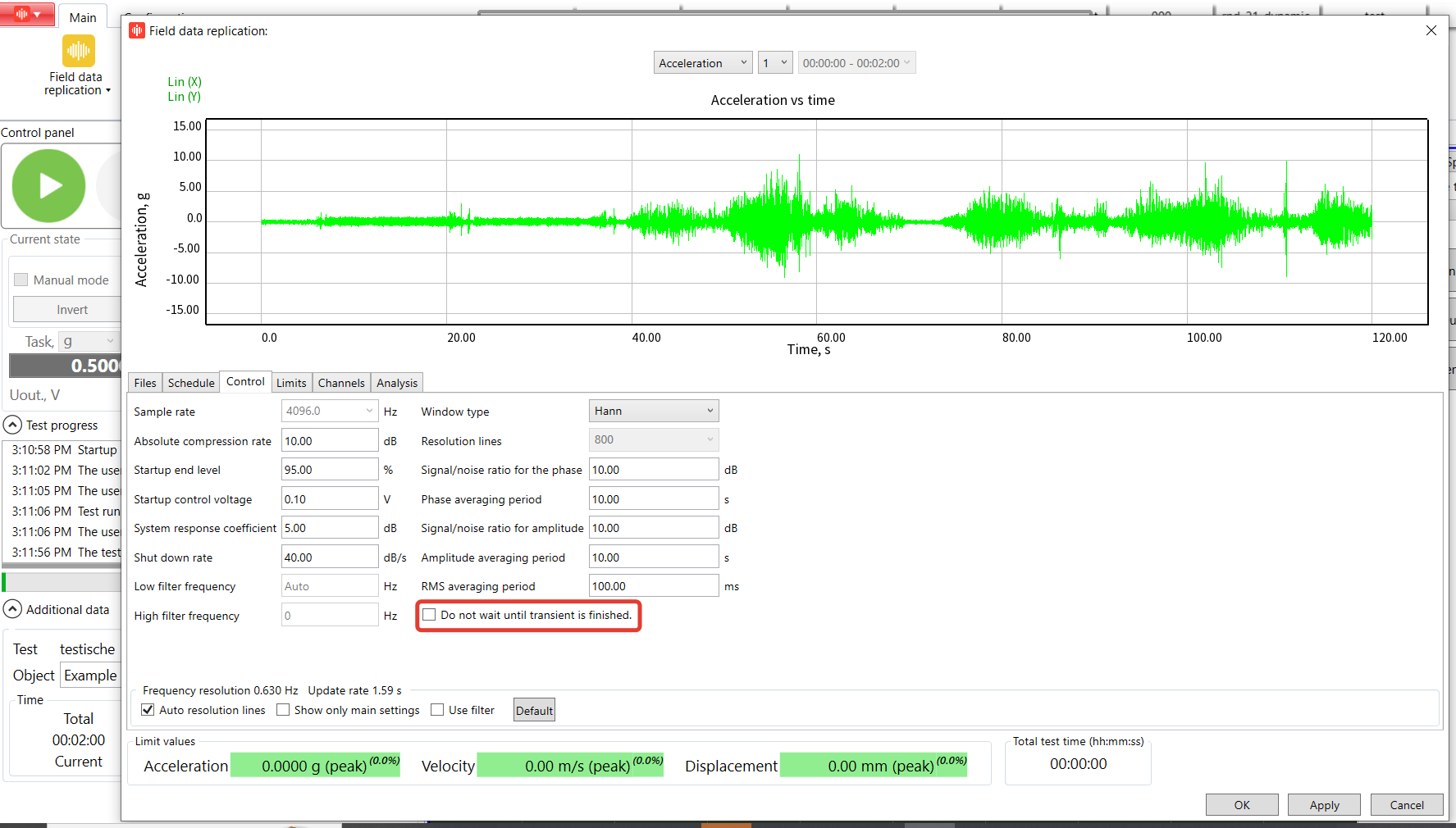

Step 4. Open the “Control” tab. It has a special feature for charge and IEPE sensors, which allows the user to ignore the zero offset and run the file.

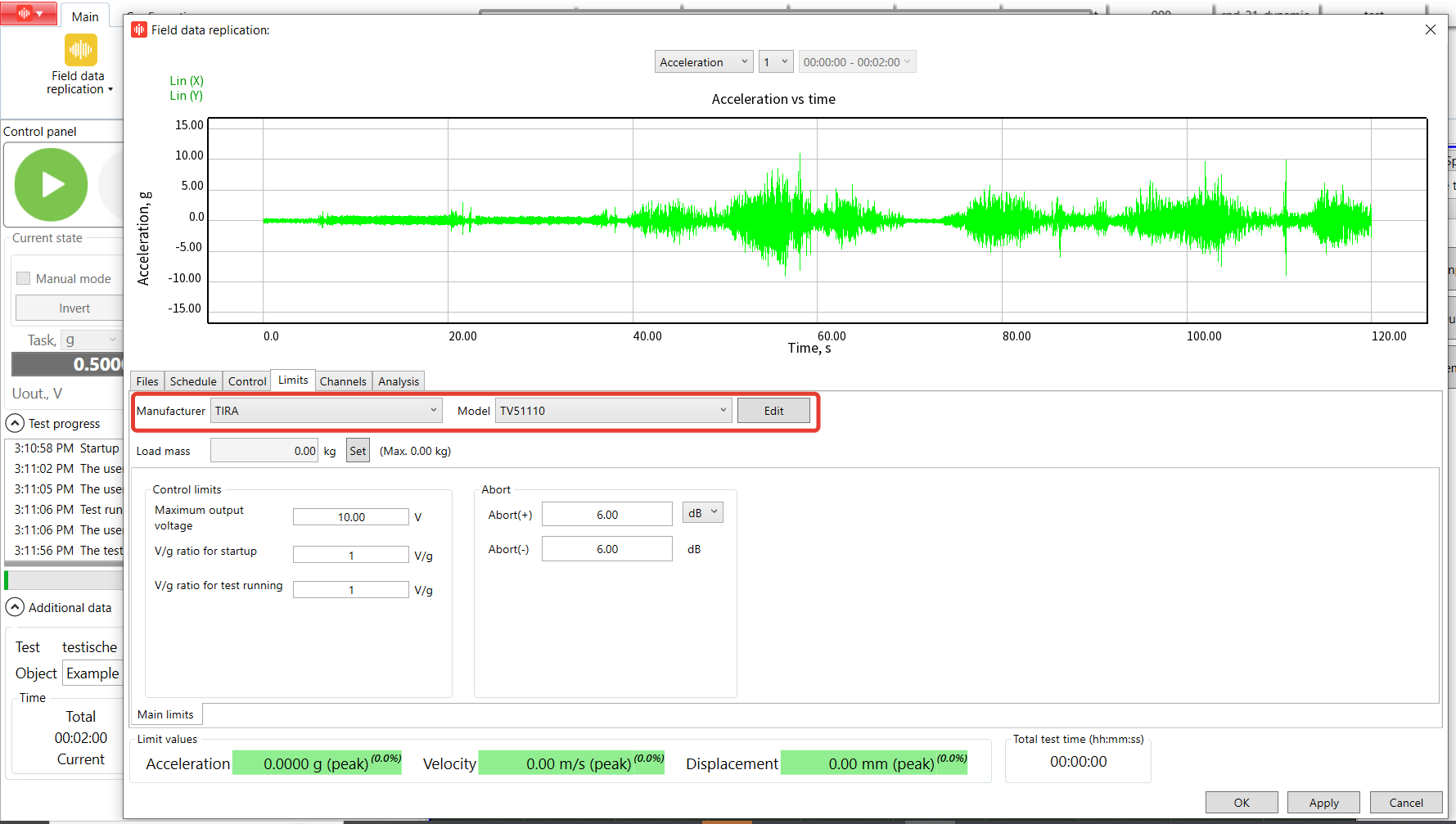

Step 5. Open the “Limits” tab and check the shaker manufacturer.

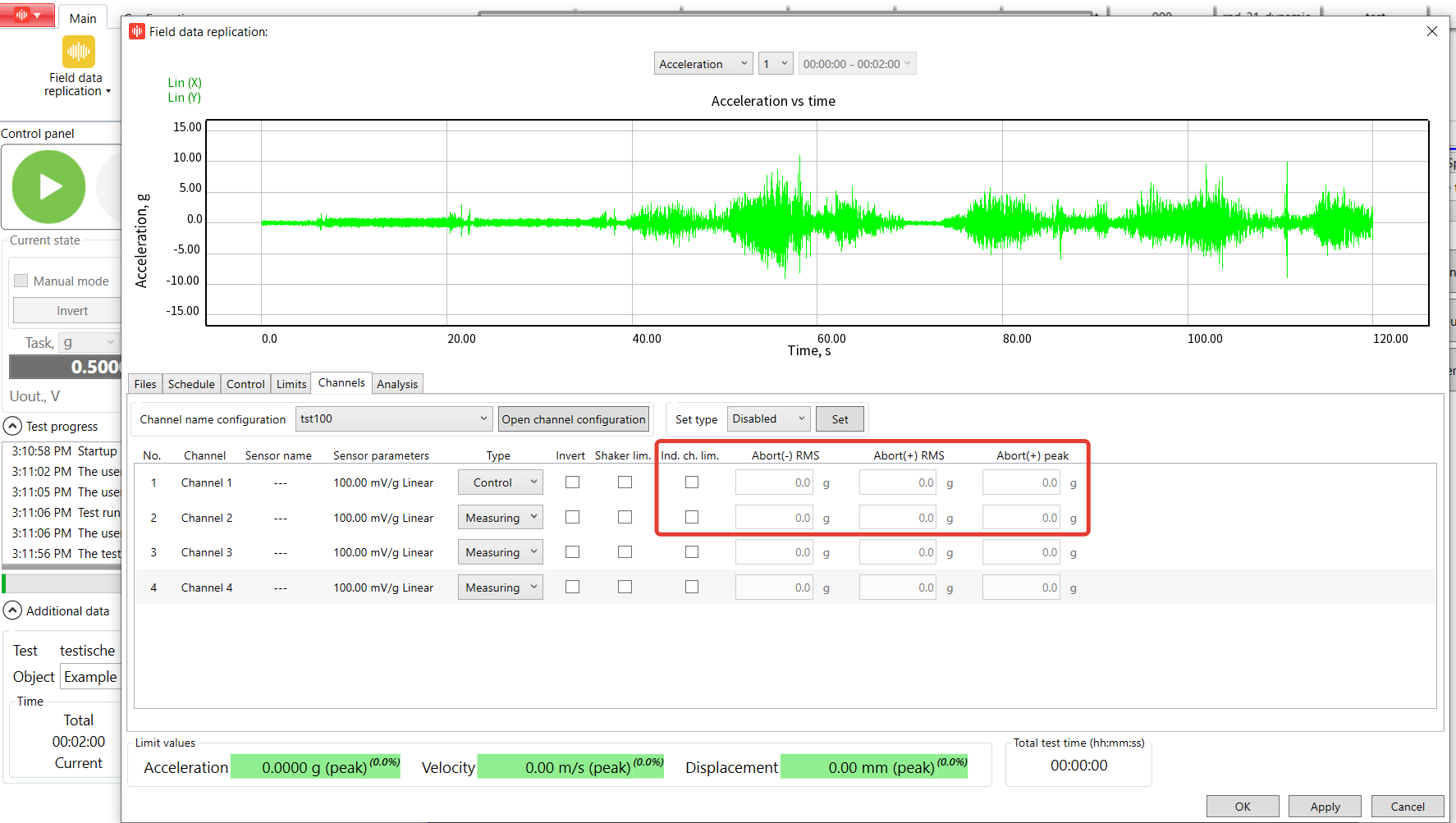

Step 6. Open the “Channels” tab and select the channels configuration. You can enable the individual limits for abort lines in RMS and peak.

The “Analysis” tab allows you to set the recording options for the test.

Step 7. The settings are complete and we can start the test!

FDR offers a highly realistic approach to testing that can significantly enhance product development, ensuring its reliable and safe work.

RULA offers top-of-the-line controllers and TestUp software for your needs, making it easy to conduct such advanced test types as FDR. To learn more about FDR test running, watch our video below.