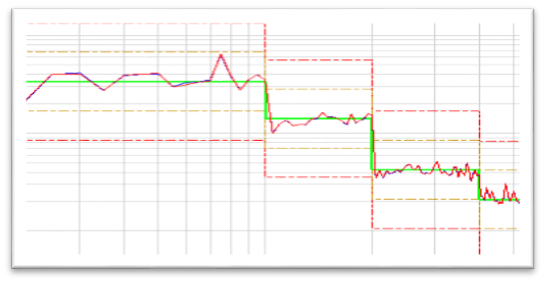

When using several shakers as one for testing a large object, it is very important to maintain a small phase shift and amplitude difference between the vibration shakers during the test.

Simultaneous impact on the object on several axes has a number of advantages:

- It saves time. There is no need to run the test on different axes consecutively. The test time is also decreased because you do not have to re-position the object on the shaker.

- It proves to be a better imitation of actual operating conditions the object undergoes.

Single-axis multishaker tests are usually run when it is not possible to mount the object on one shaker due to the size of the object.

In single-axis tests, it is recommended to fix the object on the shaker in such a way that there is room for some asynchronous vibration (in other words, there is some phase shift between the shakers, which doesn’t allow damaging the shaker or the object).

Note: on resonant frequencies of the object or fixture, the phase shift may increase.

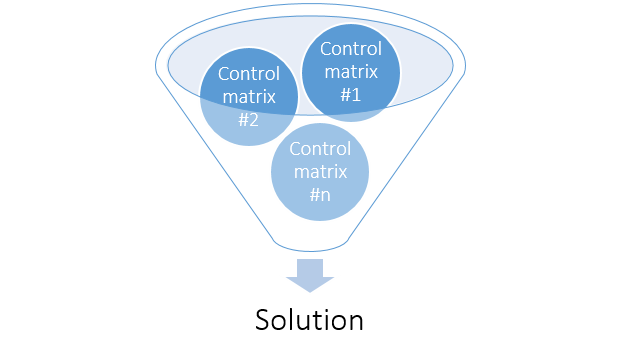

RL-C21 and RL-C25 vibration control systems apply computation of transfer-function matrix to maintain the phase and amplitude in multishaker tests, through control of shakers interaction and non-linearity of the vibration set.

The tests available in Multishaker mode are:

The multishaker tests mode parameters for RL-C21 and RL-C25 are as follows:

- Number of control channels: 2 – 8.

- Number of control outputs: 2 – 8.

- The number of shakers: 2 – 8.

- Frequency range: 0.1 to 20000 Hz.

- Maximum number of control lines: 13000

The systems can run multishaker tests on one or several axes.

Phase shift is not more than 1°.

In Sine mode, it is also possible to set the phase difference between the shakers (from 0° to 180°), which the system will maintain during the test.

In Random test, FDR, and Shock tests the control is in-phase, i.e. the minimum phase shift will be maintained.

In Random test mode, the system can control

- Identical signals on identical profiles for each shaker

- Signals of different waveform, but with the same frequency and PSD.

In the first case, the control of shakers is in-phase.

In the second case, the shakers will run the same profiles with a different waveform.

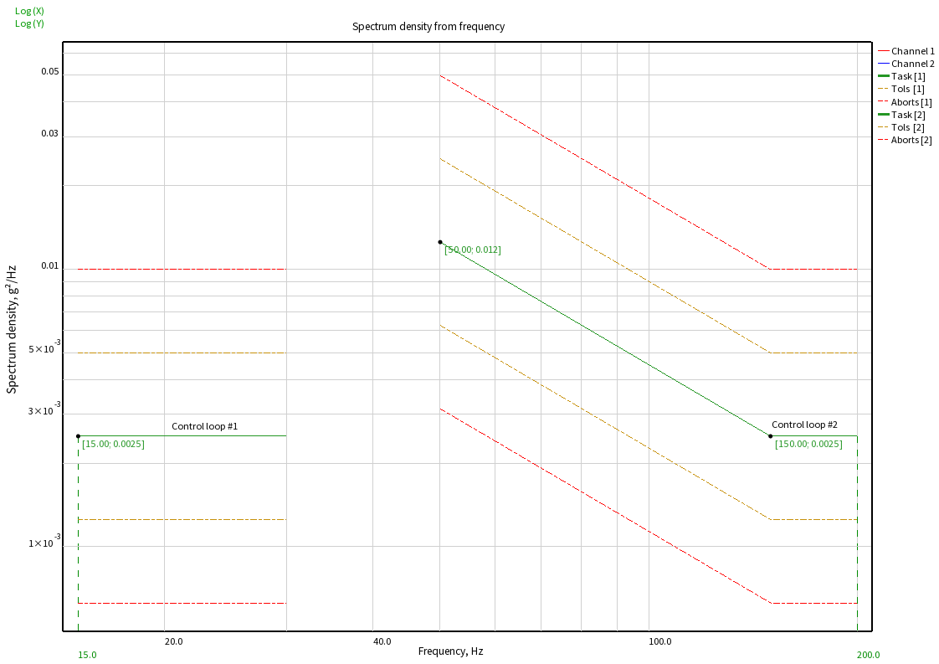

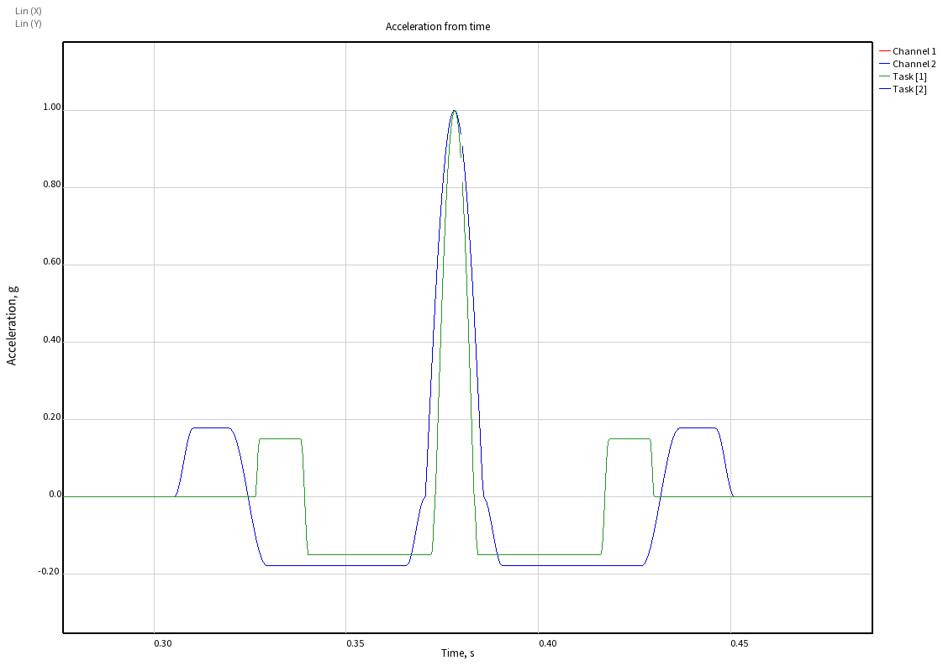

In Random tests, FDR and Shock the systems can run different profiles.

I.e. each shaker runs its own test profile, different from the others in frequency, amplitude, shape, etc.

In Shock mode, the software synchronizes different profiles by acceleration peak.

For Random tests, FDR and Shock it is also possible to set a control filter of start and end frequency.

The lower frequency of the filter can be determined automatically depending on the shaker's lowest operation frequency, or specified by the user.

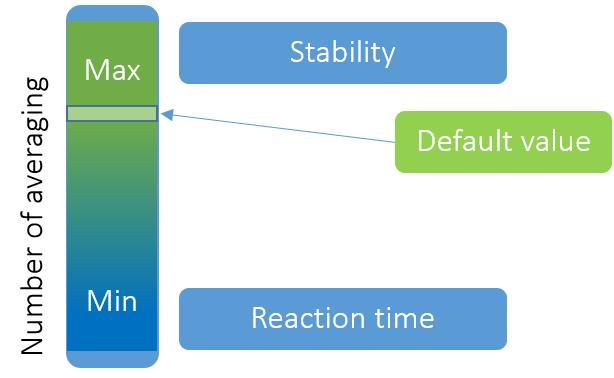

For any test type, the “number of averaging” parameter is specified.

When the parameter is increased, the work of the control algorithm is more stable, but its reaction is slower.

By default, the number of averaging is 8 to 10.

These values help to keep the right balance between stability and reaction time of the control algorithm in most cases.

For each test, it is possible to set up the control factor.

This parameter is responsible for the rigorous selection of the matrices based on their singularity. By editing this parameter, the user can adjust the sensitivity of the control algorithm (the higher the parameter, the lower is the sensitivity of the control algorithm to the singularity of the matrix).

This parameter is in direct correlation with the number of shakers in the set. For instance, for 2-3 shakers, it will be 10, for 4-5 shakers 20-30 will be a better fit, for 6 and more – 40.

The last notable parameter is the absolute compression rate for Random test, FDR, and Shock. This parameter limits the rate of control filter tuning. It is specified in dB/s. Same as the control factor, it has a direct correlation with the number of shakers in the set. For sets containing 4 and more shakers, it is usually increased to 20 dB/s (sometimes to 30 dB/s) to provide the quickest and most efficient operation of the control filter.